Plastic things have many advantages. They are lightweight, relatively durable, not bad tolerate heat and contact with water. However, the appearance of such products does not always satisfy people. After prolonged use, plastic loses its attractiveness and becomes scratched. And sometimes the color of the chosen thing is not like from the very beginning.

The solution in many cases is high-quality paint for plastic, however, when choosing it is necessary to take into account its specific features.

Features

Paint for plastic is different from formulations that are applied to other materials. Its application also has its own specifics. For example, plastic based on ABS and PVC must be coated with a special primer before painting, which should be bought at a car shop or a paint and varnish materials store. The mixture is sprayed and wiped, the treated surface dries for at least 60 seconds.

Basic requirements for staining:

- thoroughly drying and cleaning the surface, freeing it from lubricating oils, dust particles and so on,

- preliminary preparation is necessary in all cases, with the exception of applying acrylic water-based paint to polystyrene or ABS,

- the temperature of the plastic, dye and the equipment to which it is applied must be carefully balanced,

- it is desirable to heat the air to 18 degrees and above, it should be drained to 80% or less,

- only one coat is required, the average thickness of which is 60 microns,

- during drying, plastic products are kept at a temperature of 18 to 60 degrees, depending on how thick the layer is applied.

A very thin paint layer is not too strong and weakly held on the surface. If you apply more than 120 microns of paint, it will dry slowly, and decorative qualities will deteriorate sharply. The polymerization process usually takes 5 to 7 days. However, with insufficient temperature, solid humidity and increased layer thickness it may take several weeks.

Scope of application

Almost any plastic product can be painted with special coloring mixtures. Window sills and PVC windows are covered with some compounds, fiberglass and other plastics are completely different. Polyvinyl chloride is often treated with polyurethane-acrylic water-based paint. It does not give a matte effect and works well even in large areas.

The same paints and varnishes are useful if you need to process:

- siding,

- sandwich panel

- hard PVC

- building profiles,

- doors and window frames.

Acrylic enamel on water (polyurethane-acrylic paint) in most cases has two basic components. In addition to the dye itself, a hardener is included in the composition, due to which the mixture becomes resistant to mechanical and chemical destructive factors. Good curing mixtures are colorless in themselves and have no smell.

In addition, they give the paintwork material other valuable properties:

- hiding power

- decent adhesion

- resistance to ultraviolet rays.

Polyurethane paint differs in high durability. It is formed by polyurethane components with the addition of acrylates. This paintwork material solves two important tasks - it replaces both the primer and the paint composition. However, you can do without priming only if the surface is not too dirty.

Polyurethane paint is a wear-resistant substance that allows it to cover even significant areas of plastic products. Water-resistant film increases the hardness of plastic objects, not at all reducing their firmness and elasticity. Surfaces do not stick to each other after drying and retain their original attractiveness for a long time.

Regularly used items (cordless telephone, eyeglass case, toys, hand lights, instrument sticks) cover matte dye soft dot. With its help, a pleasant tactile effect is achieved. Another important advantage is the intense absorption of sound and light. In most cases, a soft dot is made black, but chemists have learned to produce brighter, more saturated tones.

Vinyl paint plastic is characterized by increased environmental friendliness, is relatively inexpensive. One unpleasant circumstance interferes with its widespread use - low resistance to destructive influences. A short contact with water or wind is enough for the plastic structure to regain an unattractive appearance.

Foam rubber products should have three qualities: resistance to ultraviolet, moisture and minor mechanical damage. It is these “opponents” that are the most dangerous for any thermal insulation, as well as other insulation structures. Spraying allows the paint to stay on the surface better, no matter which concentrate is selected.

No widely used paint can give antistatic properties to objects. As a result of this, they are provided by applying additional preparations after coloring the plastic.

Design and colors

It would be too difficult to consider all the existing options for plastic products and conclude which color and design are best for them. Therefore, it is worth paying attention to PVC-based doors and windows, which are often found in residential buildings.

When choosing a painting option, it is advisable to focus on the general style of the structure. If you need to decorate a house in the Russian style, it is worth maintaining a balance between the colors of windows, doors and the tone of the roof. Natural shades will be appropriate here. Dark brown paint may be used. It perfectly conceals drips from the rain and street dirt.

Light colors (beige, yellow, bluish, orange) are recommended to be used only in combination with similar roof colors.

Minimalist style houses do not combine well with various decorative delights; the most correct way here is to use discreet tonality. If there is a desire to create a high-quality and attractive coating, it is worth using a "chrome" color.

Modern manufacturers have learned how to create beautiful sparkling and iridescent colors. Gold paint It looks elegant and chic, sometimes even somewhat pompous. Mirror paint gives a very attractive surface chrome effect. The film formed by such a composition is obtained relatively thin, but at the same time as strong and resistant to external influences. Anticorrosion properties for obvious reasons are not very important here, however, protection against negative atmospheric phenomena is very appreciated.

Soft-dot matte paint is primarily intended for those items that are constantly in contact with human hands. It is pleasant to touch them, a feeling of velvety and warmth is created. Color can be any - black, silver, bronze and so on.

Black paint with a glossy effect, according to most car owners, is great for car interiors.

Embossed (structural) paint is recommended for coating:

- moldings

- boxes of external mirrors,

- bumpers

- details of salons.

She effectively copes with any visual defects, including scuffs and cracks. The dye is able to reconstruct the original appearance of plastic, give it a characteristic roughness and hide minor damage.

It is possible to apply a coat of coatings even without special skills and experience of such work. Quick drying allows you to evaluate all the attractiveness of the texture surface in a matter of minutes. The use of an additional coat of varnish is not required.

Unlike cars, where nothing should distract the driver from the road and instrument readings, any (silver or even bright) colors can be used at home. It is only necessary to maintain a balance between different shades of the environment, adhere to the selected color temperature (cold or warm).

It is worth focusing on personal taste and how well a particular solution fits into a particular interior. For instance, silver color is far from always appropriate. By evaluating the environment in which the plastic product will be used, errors can be eliminated when choosing tonality and texture.

Selection tips

Soft-dot is ideal for interior decoration of vehicles, because it is resistant to wear, easy to apply even on vertical surfaces, helps smooth out sharp corners. Compositions of the soft-dot category can be used to paint not only plastic. However, in this case, a careful selection of a primer that matches the specific base will be required.

It is unacceptable to use solutions with vitriol as primers, since upon contact with acrylic paints this component repeatedly weakens their positive qualities and interferes with adhesion.

Aerosol cans can be used no matter how great your painting skills are. This method of staining is very convenient. In this case, the choice of colors is huge.

Aerosol dyes can also be presented in soft dot format. The advantages of their use are reliable overlap of small deformations and the ability to form a truly original decor. On the other hand, no one forbids you to use monad enamel to create a bright gloss.

Additional advantages of aerosols are:

- the possibility of combining with other painting tools,

- ease of use

- the ability to simulate any kind of surface,

- long period of preservation of color brightness.

- Also, the remaining unspent aerosol paint can be stored for a long time inside the container. Applying a dye to a significant area in this way is more economical than using other options. In addition, it is difficult to find a better way to overlap the previous layer.

- The spray can must be kept at a distance of 25 - 30 cm from the surface during operation. It is important to constantly move your hand without stopping anywhere. Otherwise, not too elegant streaks may occur that will spoil the appearance of the surface. It is worth considering that spray painting occurs in two layers, so the paint consumption may be higher than the calculated one. When choosing a dye, one must take into account that aerosols are not suitable for mixing colors and creating a clear boundary between colored and unpainted spaces.

- It is unacceptable to use mixtures based on acetone as a paint for plastic. They are inexpensive, but there is too much risk of damage to the product.

- It is important to remember that polystyrene, polyethylene, polycarbonate and polypropylene are not stained with any formulations. Do not even try to pick up paint for them.

- Liquid plastic looks like paint. It is considered universal, but before using it, it is necessary to thoroughly study the composition, chemical properties and find out whether the mixture is suitable for a specific purpose.

- If your own knowledge and skills are not enough to carry out high-quality work, or an attempt to paint the plastic did not lead to anything, it’s worth contacting specialists for advice, and not continuing independent experiments.

How to properly paint a plastic part, see the next video.

Types and composition of paints and varnishes for plastic

Paints for plastic should not only create a coating with a decorative appearance, resistance to moisture, detergents, abrasion, but also be technologically advanced during application. In accordance with the composition they are divided into species.

- Paint on plastic, with the characteristics of soil, enamel: plastic ABS polymer, polyarylate.

- Abrasion resistant paint on plastic incorporates acrylic polyurethane resin, which provides gloss to the car.

- Tactile soft touch creates a velvet feel due to the existing component - binary acrylic polyurethane,

- Structural plastic paint is used in cases where the surface has defects that must be masked. This paint has an increased thixotropy and creates a durable glossy finish.

- PVC plastic paint has special adhesive components that increase resistance to ultraviolet radiation, moisture and other aggressive factors.

Let us consider in more detail some varieties of plastic coatings for cars, their technical and operational characteristics and especially the application to structural elements and vehicle parts.

Why use soft touch

Matte paint on soft touch plastic is specially designed for painting products whose surface is in constant contact with the fingers. It is used in the manufacture of tablets, mobile phones, furniture fittings, household appliances. Products painted with soft touch are pleasant to the touch, a velvety surface gives a feeling of softness and warmth.

Matte paint for soft touch plastic is widely in demand in the manufacture, repair and tuning of vehicles. It is used for decorating the passenger compartment. The soft touch paint with the supplied rheology allows you to easily paint vertical surfaces. This type of paintwork conceals the sharp corners of the structures of the passenger compartment.

Painting products and soft touch designs is easy even for inexperienced car owners. The process is simple and consists of several stages.

- Working material is being prepared. In a ratio of 1: 3, the hardener is mixed with a diluent.

- The resulting composition is added to the base with constant vigorous stirring. The ratio of hardener to base is 1:98. Ready-made working material can be used within 4 hours after preparation.

- The surface of the painted parts of the passenger compartment must be clean, dry and not greasy. If necessary, it can be wiped with an alcohol-containing solution.

- Painting is carried out in a thin layer. Soft-touch should be dried for 2-3 hours, in a warm room. It will be possible to use a car in a day, when the complete polymerization of the coating occurs.

This two-component composition has a high wear resistance, light and sound absorbing properties. It has excellent adhesion to PVC and ABS.

What is the difference between painting PVC surfaces

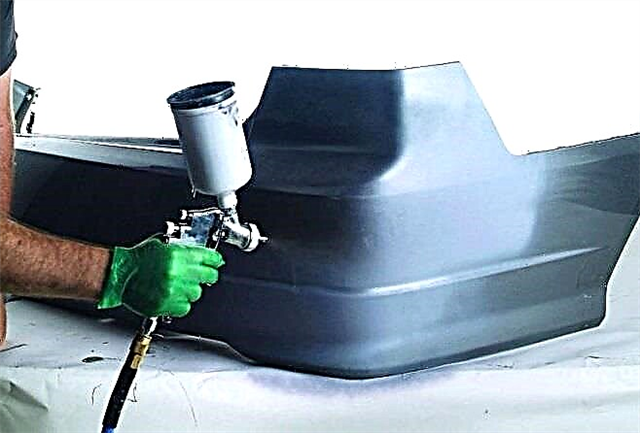

In modern auto production, auto parts and designs are made of polypropylene and only some of them are made of PVC. PVC plastic can be painted, it is amenable to paintwork. Painting PVC plastic differs from painting other types of surfaces in that it is first necessary to apply a special primer. This can be done by wiping or spraying, after which it is necessary to allow the surface to dry and then proceed to staining.

You can also use paintwork materials such as PVC plastic paint. Such a material has in its composition impurities that increase the adhesion, reliability and wear resistance of the coating of vehicle parts and structures. Structural paint for plastic has increased adhesion and a high degree of elasticity to the plastic surfaces of the car.

It is weatherproof and heat resistant. Structural paint is used for repair and tuning of bumpers, side trims.Painting plastic cases, exterior mirrors with this type of paintwork allows you to restore the damaged structure of structures that will take on their original appearance.

This paint is intended for coloring plastic products of all types, with the exception of polyethylene.

Methods for creating a mirror surface on plastic

Many car owners prefer to paint the exterior plastic parts of the car in chrome to create a mirror surface. A similar result is achieved by one of the methods below. So that you can decide which one to choose, consider each one. The first method consists of the following steps.

- Plain black paint is applied to the prepared surface.

- After the layer has completely dried, the painted structural element or part is polished to a mirror state.

- The finished mirror surface is thoroughly wiped with a cloth soaked in a special solution.

- With the help of a building hair dryer, the product heats up, after which chromium is sprayed.

- When the chrome is completely dry, the part must be polished again.

It is important to remember that the chrome plating of plastic parts must be done with a small amount of paintwork, which is located in the spray gun and is supplied under fairly high pressure.

In the second method, the car part must be painted with varnish. For this, a black base is applied, which, after drying, is carefully varnished. If a large shagreen appears during this process, then polishing should be done. For this method, it is important to thoroughly dry the varnish to dry completely. Otherwise, there will be no brilliance and mirror effect.

Specialized plastic paint is available in different packages, which affects its cost.

Paintwork material in tin containers is convenient for transportation and has a lower cost. Such containers do not allow air to pass through, which prevents the formation of a surface film. Aerosol cans are more expensive, but they are more convenient to use.

Such packaging saves a lot of time for the master, since there is no need to use a brush or spray gun. LKM from a spray can is evenly sprayed on details. Azrozols allow you to easily paint hard-to-reach spots of car structural elements.

Description

Plastic paints have significant differences from other paints and varnishes. The use of this type of dye has its own nuances and features, for example, if you need to paint plastic made of PVC or ABS, then first you need to apply a layer of a special primer, which is sold in specialized stores of paint and varnish products.

Liquid plastic is a solution of pigmenting substances in a polymer suspension, in this liquid the plastic is in dissolved form, an inorganic or organic solution is used as a solvent. Some people think that plastic paints are those paints and varnishes that can only be applied by an automatic method, after which it is necessary to heat-treat the painted layer. Heat treatment is needed, but dye can be applied not only from the spray gun, but also by various other methods.

Main advantages

Liquid plastic has the following main advantages:

- good penetration rate. Due to this, plastic paint penetrates into all, even the smallest pores, fills them and creates a reliable layer on the surface that repels water and protects the plastic from damage,

- resistance to ultraviolet rays. The paint, while in the sun, does not fade, does not change its color over time,

- excellent wear resistance, resistance to mechanical stress,

- chemicals do not damage the painted layer,

- resistance to atmospheric factors, precipitation.

Plastic paint example

Today, many varieties of dyes are made for plastic. For example, you can consider a fairly popular economical version of liquid plastic - PS-160 paint. The cost of this dye is low, its price is not more than 100 rubles per 1 kilogram.

The manufacturer produces this plastic paint from the following ingredients:

- polystyrene

- pigment substances

- organic solvent

- special additives.

In this dye mixture, small pieces of polystyrene are dissolved in toluene, dye pigments are added to this solution. After application and evaporation of toluene, a colored layer remains on the plastic, forming a solid protective layer.

Specifications

Each plastic paint has its own individual properties and characteristics. For example, you can cite the parameters of the common coloring mixture PS-160:

- the drying period of one layer is about 1 hour,

- the consumption of plastic paint when applied by pneumatic spraying is 200-220 g per square meter,

- the volume of non-volatiles in the applied layer is 23-30%. This indicator will depend on how thin the paint is with the solvent.

- the resistance of the dried layer to the static effect of a liquid at room temperature is at least two days.

Attention! As a thinner, a plastic paint manufacturer recommends the use of toluene. In addition to it, you can use a solvent, but you should not dilute the composition with white spirit or acetone, since they convert the paint into an emulsion, this will adversely affect the quality of the protective layer. The instructions for plastic paint will necessarily indicate which solvent can be used to dilute the composition.

Varieties

Today, several varieties of plastic paints are made for processing plastics and other materials. Here is a list of the main, most popular types:

- Acrylic water enamels or polyurethane-acrylic compounds. Most often they are produced in two different containers, in one of them there is a base, in the other - a hardener. Before applying the paint, these components must be mixed together, so that the painted layer will be resistant to chemical and mechanical effects. Acrylic compositions have an excellent indicator of adhesion, hiding power and resistance to ultraviolet rays.

- Polyurethane dyes have a high strength index. These formulations are a mixture of polyurethane and acrylate components. Polyurethane plastic paints at the same time play the role of a primer and a dye. If the surface is clean, you can not prime it beforehand. Although polyurethane compounds are not cheap, their cost is fully paid for by its excellent wear resistance. In addition, these mixtures are very economical in consumption, have high water resistance, have good elasticity and resilience. Polyurethane coating for a long time retains the external attractiveness and reliable security of the product.

- Soft touch is a special rubberized paint that is used for mobile phones, tablets, laptops, eyewear cases, flashlights, toys, tool handles, and many other items. The painted surface is very pleasant to the touch, it is able to absorb light and sound, has good scratch resistance. Things after painting do not slip in the hands, on them the paint creates a pleasant, warm and soft layer. Thanks to this rubberized paint, the products do not wear out for a long time. This mixture can be applied to wood, metal, plastic, polymeric materials and many other surfaces.

- Vinyl dyes are environmentally friendly substances that are relatively inexpensive. Although vinyl compositions have several advantages, they have very low strength, the coating quickly scratches, collapses, becomes unattractive. Therefore, these paints are used less and less in our time.

Preparation before painting

Before painting plastic or any other material with liquid plastic, it is important to complete the preparatory steps:

- with a damp cloth or brush, any dirt, such as dirt, debris, dust, is removed from the surface,

- with a rag and organic solvents, degrease the material so that it does not have greasy, oily stains,

- if the metal surface is painted, it must be cleaned (preferably to a shine) with a metal brush or sandpaper from rust, corrosion, slag, scale,

- a layer of old paintwork is removed. The best option is sandblasting, but if you don’t have such equipment, you can use an electric or manual grinding tool.

If there is rust on a metal surface, it is advisable to treat it with a special rust converter before painting. This solution quickly reacts with a layer of rust, resulting in a strong, insoluble layer. But if there is formation rust on the material, it is best to remove it mechanically. After cleaning, it is recommended to prime the surface, but this is not necessary. Primed base or not, should be indicated in the instructions for use of the ink mixture.

Attention! After cleaning the metal, you need to start staining no later than 6 hours. Otherwise, moisture in the air will begin to provoke corrosion processes, and cleaning will have to be repeated again.

Staining process

To paint plastic or other materials is desirable not in one but in two or three layers. Various tools are used for staining, some coloring mixtures can be applied only with a spray gun, while others are applied with a roller or brush. If a spray gun is to be used, the hose on it must be resistant to organic solvent.

You can paint in the temperature range from +5 to +30 degrees, air humidity should not be more than 70%. It is not recommended to paint plastic or other surfaces at temperatures above 25-30 degrees, otherwise the coating may peel off quickly. In addition, you should not paint if the temperature drops too quickly, this can lead to precipitation and the formation of condensation, and damp materials should not be painted. On the street you can not paint in rainy weather and in fog.

Useful tips from specialists

During staining, experts recommend adhering to such recommendations:

- when painting indoors, you must take care of high-quality ventilation or ventilation of the room. If it is not possible to organize ventilation, it is better to paint in fresh air, as the paint may contain organic solvents that adversely affect the respiratory system and the entire human body,

- during painting, it is imperative to use personal protective equipment and safety, such as tight protective clothing, glasses, rubber gloves and a respirator,

- in the store you need to purchase in advance a sufficient amount of paint and all the necessary painting tools,

- Before painting plastic, you can do without preliminary preparation. But if you have to paint metal, wood, concrete, plaster or other materials with plastic paint, you definitely need to carry out preparatory work,

- if you need to paint an uneven, broken surface, it is better to use an aerosol spray. When using it, the spray nozzle should be at a distance of about 25 centimeters from the base to be painted,

- during painting, it is important to ensure that there are no leaks and sagging of the coloring mixture, as they will spoil the appearance of the product

- in multi-layer application, it is necessary to wait until the previous coating has dried, this requires several hours before applying each subsequent layer.

So, plastic paints are very popular today. Liquid plastic effectively protects the surface, making it externally attractive and durable. Following the recommendations for staining, the dye will look beautiful and will firmly adhere to the surface.

Areas of use

The range of use of dye for plastic is quite wide, but most often it is used:

- For painting dashboards of boats and cars. Painting panels is necessary not only for the purpose of decoration, but also to give them additional strength. This is especially true for panels and other plastic parts of boats, which are located on the deck and are exposed to the weather.

- In order to decorate various household items and interior decoration. Dyes for plastic can decorate furniture, beautifully design wall panels or paint plastic bottles. From such bottles, craftsmen create real works of art, skillfully combining the colors of produced bottles and additional coloring.

Paints for plastic can be used everywhere, the main thing is to choose the type of dye in accordance with the type of plastic and the operating conditions of the product.

What to look for when choosing

When deciding which type of dye to purchase, you must carefully familiarize yourself with the main characteristics of the composition indicated on the package:

- Adhesion. Most dyes have good adhesion to the surface, differ only in the degree of adhesive properties. When choosing, you need to consider what kind of composition and smoothness the plastic object is planned to be painted.

- Compatibility with the base. Enamel for plastic should be suitable in composition to the type of surface to be painted or to the soil applied to it. Failure to comply with this rule will lead to the fact that the decorative layer will quickly crack or go bubbles.

- Spreadability and hiding power. These parameters show how even, with a thick layer the paint lays on the material.

- Water resistance. All acrylic paints and varnishes used for plastic surfaces are water resistant, and after drying, the resulting film can be washed. But for products in high humidity, in order to increase water resistance, additional additives are added, often polyurethane.

- Aesthetics. Depending on what kind of result you need to get, you can use plastic paint, giving a flat, smooth surface, or choose structural painting.

- Compliance basis. The instructions always indicate what kind of plastic can be painted with this tool.

Do I need to be primed

It is known that preparation for painting for all coloring agents consists of the following steps:

Some varieties of plastic do not need priming - they can be painted immediately after degreasing, skipping one of the stages of preparation. But how to determine whether to prime or not?

At home, this can be done in two ways:

- Set fire to a small plastic piece. If during burning the flame smokes a lot, then priming is not necessary. This should be noted for those who prefer to primer plastic bottles to improve the quality of work. When burning, the bottles are very spoiled, so it is quite possible to save time and money by skipping the primer.

- Dip in water. Drowned plastic parts do not need to be applied with soil mixtures.

Important! If it is not possible to carry out these simple tests, for example, if the wall panels have been installed for a long time and there are no pieces of residue for examination, then it is recommended not to neglect the primer work.

Necessary materials

Before you start painting, you need to stock up on the following tools and materials:

- A set of "skins" of different grain sizes.When preparing the material, they can give the base the necessary smoothness and roughness.

- Water and detergent (it is better to take a neutral soap).

- White spirit or any other plastic degreaser.

- Masking tape (if you need to paint not the entire product, but only part of it).

- Painting tool: spray gun, roller, brush or spray can.

Having prepared everything you need, you can begin to work.

Painting process

Before applying the paint, preparation of the base is necessary. To do this, the surface needs:

- To wash. Small parts are immersed in water, and a portable car wash is recommended for large areas.

- To process with a "skin". Depending on the smoothness, the base is either polished or, on the contrary, scratched with sandpaper.

- Degrease. White spirit is most commonly used for this purpose, but any other alcohol-based degreaser can be used.

- Primer if necessary. If in doubt, to primer or not to primer, then a primer should be applied. An extra primer will only improve the quality of the final result.

- Dry and you can start painting.

When painting, it is recommended to consider the following:

- What is the load on the product. The greater the likelihood of abrasion or damage to the surface, the more layers must be applied.

- A new layer can be applied only after the complete drying has already been applied.

- It is recommended to use the painted product one day after applying the last coat. During this time, the complete polymerization of the material will occur, the decorative film will acquire all the strength characteristics.

By following these simple recommendations, you can make high-quality and beautiful coloring of the product. Using paints for plastic products, you can not only give a second life to old things, but also additionally strengthen plastic parts.