Table of contents:

It is completely excusable that people who are not engaged in professional construction do not have an idea about some of the features of finishing and other materials. For example, MDF. This material enjoys steadily growing popularity, however, there are more questions than answers regarding its properties. Consider the main characteristics, the scope and its typical sizes.

What kind of material is this? Decoding abbreviations

MDF is an abbreviation that came from English. In the literal translation, the name of the material sounds like MEDIUM DENSITY FIBERBOARD. The first letters of these words served as the basis for creating a familiar colloquial term. Translated into Russian, the name of the material stands for medium density fiberboard.

Composition and Characteristics

By its structure, MDF is a fiberboard made up of shredded sawdust. In the manufacturing process, the raw material is cleaned of sawdust and converted to a powder state. Then the resulting composition is treated with steam and an adhesive base is added: lignin and paraffin.

Among the main advantages of MDF are the following characteristics:

Resistance to dynamic loads. To break the MDF panel, it is necessary to apply a force equal to 15 MPa. Accordingly, by mechanical properties. The material is significantly superior to wood.

Environmental Safety. The release of formaldehyde from the panels must meet the requirements of:

| Test method | Air release rate | Test assignment |

| Chamber method according to GOST 30255-95 | no more than 0.124 mg / m 3 of air | Qualification and control periodic tests |

| Gas analysis method according to GOST 53867-2010 | no more than 3.5 mg / m 2 per hour | Production control |

Reliability. The material has increased moisture resistance, is absolutely neutral to temperature extremes and direct sunlight.

Simplicity in processing. With high strength, MDF is easy to process, if desired, you can decorate the panel with decorative clipping.

Density. MDF from 600 to 850 kg / m3 Fiberboard is also produced in low density (LDF) from 200 to 600 kg / m3 and high density (HDF) over 800 kg / m3.

It should be noted that fungus and mold do not appear on the plates.

MDF or PVC: which is better?

It’s worth immediately clarifying that two finishing materials (MDF and PVC) are widely used in home construction, and have no complaints about quality. Therefore, when choosing, you need to focus on the field of application. For example: MDF is considered more environmentally friendly, so it is suitable for decorating a nursery or a hall without problems. PVC is immune to any aggressive influences, therefore it is often used to design bathrooms and kitchens.

It is worth noting that PVC has a minimum weight, so when installing it is quite possible to do it yourself. However, this material is very susceptible to mechanical damage, so even a slight blow can damage the surface. MDF is more resistant to external influences, but it can not be for a long time in a humid environment.

Types of wood - fibrous material

In the domestic market there are many varieties of MDF, so problems with the choice of finishing options usually do not arise. The assortment of construction stores usually includes the following categories:

Laminated. A special film is applied to the surface, which gives typical panels various shades. The surface can be matte or glossy.

Veneered. This is quite expensive stuff. Here, veneer made of valuable wood is glued on both sides of the panel.

For painting. This is a special kind of MDF, designed for self-staining. The surface is coated with a special composition that provides adhesion with dyes.

Wall panels. Such products are very convenient in terms of installation for interior decoration. Here, the “groove-lock” fastening system is used, which ensures reliable adhesion of the elements to each other. It is worth noting that wall panels are attached with a stapler or glue.

Moisture resistant. This material is impregnated with a special composition, so it can be in high humidity conditions for a long time. By their properties, such panels are very similar to PVC.

Flexible. The material is resistant to dynamic loads, so it can bend without getting mechanical damage. Typically, such panels are used in the design of arches.

MDF is used to make interior doors, decorative aprons for the kitchen, and facades for cabinet furniture. The external parameters depend on the type of application.

Overall dimensions of material

Depending on the area of application of MDF, the dimensions of the facing material also change. Here you can derive the following standards:

Wall panels. The standard length of the wall panel is 2.62 metershowever, some manufacturers produce products that are long 2.44 and 2.8 m. Width may vary within 100-900 mm. Panels, depending on the width, are divided into types P-1, P-2, P-3, P-4, P-5 (100, 125, 150, 175, 250). With panel thickness 3-30 mm. The thickness of veneered MDF can reach 60 mm.

Compliance with quality requirements:

| Resistivity with normal separation of the coating. MPa, not less | 0,4 |

| Resistance to abrasion, revolutions, not less | 30 |

| The hardness of the protective and decorative coating, microns. no more | 120 |

| Warp, microns / m, no more | 1.5 |

Slabs. The length of the material is usually around 1.5 meters, width - 100-900 mm. The thickness of the MDF boards varies within 6-24 mm.

Facades. Given the various options and dimensions of furniture, there are no strictly defined standards. The basis can be considered such parameters: thickness 16 mm height 140-934 and width - 296-596 mm.

Aprons. For the manufacture of decorative aprons, furniture panels are usually used that have the following characteristics: length - 3 000, width - 600 and thickness 6-10 mm.

Countertops. This element should be resistant to dynamic loads, so the following dimensions play here: length - 1 000, width - 600 and thickness 28-38 mm.

It is worth noting that the dimensions given may vary, depending on the manufacturer.

Table of parameters of polished sheets.

| Manufacturer country | Dimensions (mm) | Sheet thickness (mm) | Density (kg / m³) | Sheet weight (kg) |

| Russia | 2440×2050 | 3 | 840 | 13 |

| Russia | 2440×1830 | 3 | 840 | 12 |

| Ukraine | 2800×2070 | 3 | 780 | 15 |

| Russia | 2800×2070 | 6 | 750 | 26 |

| Ukraine | 2800×2070 | 6 | 780 | 27 |

| Germany | 2620×2070 | 6 | 800 | 26 |

| Russia | 2800×2070 | 8 | 750 | 35 |

| Ukraine | 2800×2070 | 8 | 780 | 36 |

| Germany | 2620×2070 | 8 | 800 | 35 |

| Russia | 2440×1830 | 10 | 800 | 36 |

| Russia | 2800×2070 | 10 | 750 | 43 |

| Ukraine | 2800×2070 | 10 | 770 | 45 |

| Germany | 2620×2070 | 10 | 790 | 43 |

| Russia | 2800×2070 | 12 | 750 | 52 |

| Ukraine | 2800×2070 | 12 | 770 | 54 |

| Germany | 2620×2070 | 12 | 790 | 51 |

| Russia | 2440×1830 | 16 | 800 | 57 |

| Russia | 2800×2070 | 16 | 750 | 70 |

| Ukraine | 2800×2070 | 16 | 770 | 71 |

| Germany | 2620×2070 | 16 | 790 | 69 |

| Russia | 2440×1830 | 18 | 800 | 64 |

| Russia | 2800×2070 | 18 | 730 | 76 |

| Ukraine | 2800×2070 | 18 | 750 | 78 |

| Germany | 2620×2070 | 18 | 770 | 75 |

| Russia | 2800×2070 | 19 | 730 | 80 |

| Ukraine | 2800×2070 | 19 | 750 | 83 |

| Germany | 2620×2070 | 19 | 770 | 79 |

| Russia | 2800×2070 | 22 | 730 | 93 |

| Ukraine | 2800×2070 | 22 | 750 | 96 |

| Germany | 2620×2070 | 22 | 770 | 92 |

| Russia | 2440×1830 | 24 | 800 | 86 |

| Russia | 2800×2070 | 25 | 730 | 106 |

| Ukraine | 2800×2070 | 25 | 750 | 109 |

| Germany | 2620×2070 | 25 | 770 | 104 |

| Russia | 2800×2070 | 28 | 720 | 117 |

| Ukraine | 2800×2070 | 28 | 740 | 120 |

| Germany | 2620×2070 | 28 | 750 | 114 |

| Russia | 2800×2070 | 30 | 720 | 125 |

| Ukraine | 2800×2070 | 30 | 740 | 129 |

| Germany | 2620×2070 | 30 | 750 | 122 |

| Germany | 2620×2070 | 38 | 750 | 155 |

| Germany | 2620×2070 | 40 | 750 | 163 |

| Germany | 2800×2070 | 40 | 740 | 172 |

Table of parameters of laminated sheets.

| Manufacturer country | Dimensions (mm) | Thickness (mm) | Number of Laminated Sides | Weight, kg) |

| Russia Ukraine | 2800×2070 | 16 | 1 | 74 |

| Russia Ukraine | 2800×2070 | 16 | 2 | 74 |

| Russia Ukraine | 2800×2070 | 19 | 1 | 88 |

| Russia Ukraine | 2800×2070 | 19 | 2 | 88 |

| Germany | 2620×2070 | 10 | 1 | 43 |

| 2620×2070 | 16 | 1 | 69 | |

| 2620×2070 | 18 | 1 | 78 | |

| 2620×2070 | 19 | 1 | 82 | |

| 2620×2070 | 22 | 1 | 95 |

Table of parameters of sheets coated with paper film.

| Dimensions (mm) | Thickness (mm) | Weight, kg) |

| 3 | 2440×1830 | 11 |

| 4 | 2440×1830 | 14 |

| 6 | 2440×1830 | 21 |

| 6 | 2800×1830 | 25 |

| 8 | 2800×1830 | 33 |

| 10 | 2440×1830 | 36 |

| 10 | 2800×1830 | 41 |

| 12 | 2800×1830 | 49 |

| 16 | 2440×1830 | 57 |

| 16 | 2800×1830 | 66 |

| 18 | 2440×1830 | 64 |

| 18 | 2800×1830 | 74 |

| 19 | 2800×1830 | 78 |

| 22 | 2800×1830 | 90 |

| 24 | 2440×1830 | 86 |

| 25 | 2800×1830 | 102 |

What is MDF panel

MDF panels - this is such a facing material, which consists of wood sawdust and binders. Sawdust is heated and pressed under high pressure. The result is a wood chipboard. With its appearance, it resembles a single piece of a noble tree. However, its price is relatively lower. MDF panels are also popularly called lining. After heat treatment, a melamine film is applied to the plates to simulate the porous structure of a noble tree. To give such a finished material the desired shape and size using a conventional jigsaw or hacksaw.

MDF panels - this is such a facing material, which consists of wood sawdust and binders.

MDF panels - this is such a facing material, which consists of wood sawdust and binders.

Advantages and disadvantages of using MDF panels for walls

When choosing a decorative material for walls, the owner of a house or apartment should know everything about the strengths and weaknesses of this material. MDF panels are no exception. Below are their advantages:

- Wood chip wall panels have a low cost, therefore they are always available in the construction market,

- MDF panels are easy to install. To install them on the wall, you do not need to invite a master finisher. You can do everything yourself if you follow the instructions,

- Fastening plates does not take much time,

- This facing material quite plausibly imitates a real tree. It looks concise in the interior and makes the room cozy,

- Wall panels can be used as heat and noise insulation products. Insulation is simply inserted into the space between the frame and the plates. Also, using the crate and plates, you can hide communications.

This facing material quite plausibly imitates a real tree.

This facing material quite plausibly imitates a real tree.MDF boards for walls have some disadvantages. Among them are especially distinguished:

- Sometimes it’s very easy to deform such plates,

- If the panels are attached to the crate, the area in the room is visually reduced,

- Fiberboard is subject to burning. Of course, there are products coated with refractory mortar. But they cost a lot more

- This finishing material may lose its appearance from exposure to moisture, steam and temperature extremes. Therefore, it can not be used in the bathroom, pool, on the balcony and loggia, as well as in the sauna and bath.

This finishing material may lose its appearance from exposure to moisture, steam and temperature extremes.

This finishing material may lose its appearance from exposure to moisture, steam and temperature extremes.What are the MDF panels

Today, manufacturers of finishing materials offer a wide range of wall panels. They are divided into several types and have their own parameters. There are 5 criteria when choosing this material:

- What production technology are they carried out,

- What material is their front part framed by,

- What size do they have

- How can they be installed,

- What shades are on sale.

Below are the possible panel options for each parameter.

Today, manufacturers of finishing materials offer a wide range of wall panels.

Today, manufacturers of finishing materials offer a wide range of wall panels.

According to production technology

The production of wall panels takes place in large factories that have at their disposal high-temperature furnaces, pressing machines and saws, as well as the necessary raw materials for the manufacture of products. Depending on the production technology, MDF panels come in 2 types:

- The usual standard products with a low price. They can be applied in all rooms, except those in which humidity is increased.

- Moisture-resistant products are made specifically for bathrooms, toilets, kitchens and other rooms with high humidity. A chemical composition is applied to them, which protects the panels from exposure to water, steam and high temperatures.

Moisture-resistant products are made specifically for bathrooms, toilets, kitchens and other rooms with high humidity.

Moisture-resistant products are made specifically for bathrooms, toilets, kitchens and other rooms with high humidity.On the design of the front part

I cover the front part of the chipboard with various substances to give them certain physical and external characteristics. According to the design of the front of the MDF panel are divided into:

- Laminated - coated with a special layer protecting the product from mechanical stress, steam, water and high temperatures.

Covered with a special layer protecting the product from mechanical influences, steam, water and high temperatures. Veneered - designed to decorate the room. They are covered with a rather thin layer of noble wood, so that the products acquire a beautiful appearance.

Covered with a special layer protecting the product from mechanical influences, steam, water and high temperatures. Veneered - designed to decorate the room. They are covered with a rather thin layer of noble wood, so that the products acquire a beautiful appearance.

Veneered - designed to decorate the room. Cork - the most expensive type of MDF panels. Its outer layer consists of compressed wood, which has a cork structure. Thanks to this, the plate easily absorbs any noise and can be used as a heat-insulating material.

Veneered - designed to decorate the room. Cork - the most expensive type of MDF panels. Its outer layer consists of compressed wood, which has a cork structure. Thanks to this, the plate easily absorbs any noise and can be used as a heat-insulating material.

The plate easily absorbs any noise and can be used as a heat-insulating material. Decorative - such products imitate natural stone, wood, brick or ceramics.

The plate easily absorbs any noise and can be used as a heat-insulating material. Decorative - such products imitate natural stone, wood, brick or ceramics.

Decorative - such products imitate natural stone, wood, brick or ceramics.

Decorative - such products imitate natural stone, wood, brick or ceramics.

By manufactured sizes

The size of the MDF panels depends on their shape. For example, products made in the form of plates have a length of up to 1.5 meters and a width of 10 to 90 centimeters. The thickness of these products starts at 6 and ends with 24 millimeters.

If the product is made in the form of sheets or lining, it has a length of up to 2.6 meters and a width of 15-90 centimeters. Their thickness varies from 2.5 to 9 millimeters. Thicker panels of 60 millimeters are not used for decorative, but for functional purposes.

The size of the MDF panels depends on their shape.

The size of the MDF panels depends on their shape.

By way of laying

You can lay wall panels in various ways. Depending on this, they are divided into:

- Tile - its main features consist in a huge number of color solutions and textures. Therefore, such products are mounted on the walls to give the room conciseness and comfort,

Such products are mounted on walls to give the room conciseness and comfort. Lining - the most common panels in the installation. They are well fastened together thanks to spikes and grooves. In addition, these products have a low cost and are always available on the building materials market.

Such products are mounted on walls to give the room conciseness and comfort. Lining - the most common panels in the installation. They are well fastened together thanks to spikes and grooves. In addition, these products have a low cost and are always available on the building materials market.

They are well fastened together thanks to spikes and grooves. Sheets - are larger than the lining and because of this, a holistic picture is created. There are no special compounds in them. Using decorative seams, craftsmen twist such products together.

They are well fastened together thanks to spikes and grooves. Sheets - are larger than the lining and because of this, a holistic picture is created. There are no special compounds in them. Using decorative seams, craftsmen twist such products together.

Using decorative seams, craftsmen twist such products together.

Using decorative seams, craftsmen twist such products together.

By color

The shade range of MDF panels, presented in construction stores, pleases with its diversity. Top colors are shades that imitate the noble species of trees. For example, oak, walnut, deciduous, pine. These products are inexpensive and weigh much less than real layers of trees.

Lining reproducing leather and stone is also popular with buyers. In addition, some like slabs with patterns, drawings, ornaments or plain. They are all matte or glossy.

Top colors are shades that imitate the noble species of trees.

Top colors are shades that imitate the noble species of trees.

The cost of MDF panels for walls

The price of wall panels depends on their type, size and the manufacturer itself. Of course, domestic products can have a low cost compared to foreign ones. On average, the cheapest panels cost from 80 to 500 rubles. More expensive models with high wear resistance cost from 600 to 2500 rubles. The cost of specific products of the right size and color can be found in a hardware store.

The price of wall panels depends on their type, size and the manufacturer itself.

The price of wall panels depends on their type, size and the manufacturer itself.

Interior design options for MDF rooms with panels

MDF panels can be used in almost all rooms and can be used in almost any interior style. This finishing material can be laid on the wall in different ways:

- Bottom - thanks to this installation, you can visually increase the height of the ceilings. In addition, with this option, designers achieve the expansion of the room area due to the same visual effects. This option is good for the kitchen, corridor or hallway,

Thanks to this installation, you can visually increase the height of the ceilings. Across the entire area of the walls - this method makes the room concise, comfortable and stylish. Most often they pane all the walls in the home library, study or living room,

Thanks to this installation, you can visually increase the height of the ceilings. Across the entire area of the walls - this method makes the room concise, comfortable and stylish. Most often they pane all the walls in the home library, study or living room,

This method makes the room concise, comfortable and stylish. As a decorative element, MDF boards are used in all rooms except the bathroom. For example, designers often clad one wall with panels, emphasizing it. All the rest are covered with other finishing material. This method is typical for the living room, bedroom, kitchen and dining room.

This method makes the room concise, comfortable and stylish. As a decorative element, MDF boards are used in all rooms except the bathroom. For example, designers often clad one wall with panels, emphasizing it. All the rest are covered with other finishing material. This method is typical for the living room, bedroom, kitchen and dining room.

Designers often clad panels on one wall, emphasizing it.

Designers often clad panels on one wall, emphasizing it.

MDF boards are often used in the kitchen as an apron. In this case, moisture-resistant products with a high degree of resistance to external influences are selected. They also clad a wall in the living room and mount a TV on it or make an imitation of a fireplace below. In the bedroom, the MDF pane lining the wall, near which there is a bed.

In fact, there are a lot of options for decorating wall panels from wood-particle material. You just need not be afraid to experiment and create your own unique style.

Features

MDF is a finely dispersed fraction of wood shavings, pressed under high pressure without the use of an adhesive component in the form of phenol and formaldehydes. Wood waste is crushed. The fine wood fraction undergoes heat treatment, as a result of which an adhesive fragment is released - paraffin or lignin. The glue fragment sticks together the mass, and the necessary strength is given by pressing.

It is worth noting the environmental friendliness of MDF - the plate contains only natural, safe substances for use: wood and carbide resins, which are not harmful to humans.

The process of industrial production of MDF is the same as the technology for the production of chipboards. The difference is that the composition of the particleboard includes formaldehyde resins that are harmful to human health. In terms of ease of use in the construction industry, chipboard is inferior in the reliability of their fixing with screws. After some time of use, it is possible to loosen the holes and the screws to fall out, it is impossible to fix this chip, while repairing, it is necessary to use another place for fastenings. MDF boards have a denser structure, which allows you to reliably hold fasteners.

MDF board has such a property as durability, it is well resistant to mold and rot. This material shows sufficient water resistance, which allows it to be used even in rooms with high humidity, for example, in the kitchen. Plates from the finely dispersed fraction of wood chips have excellent performance: they do not warp and do not deform. They carry a large payload due to their strength, a great advantage is the flexibility when heated to create curved coatings. The disadvantage is flammability.

A melamine film or veneer is glued to the surface of the plate. The surface acquires a beautiful decorative appearance, however, the disadvantage is the low resistance to mechanical stress. Such damage is quite simple to repair by painting with a suitable color paint. Lamination with a film gives the plate an almost indistinguishable resemblance to natural material, while the price remains affordable.

The film has various colors and textures, which justifies the widespread use of MDF panels for interior decoration.

MDF panels have gained great popularity due to the ease of installation. Even beginners in the construction business without difficulty will be able to independently clad walls or floors. Repairing failed several panels will require simple replacement with new parts in the coating. The panels allow you to hide electrical and other communications under the inner frame. It is hygienic material, easy to clean. It can be washed with ordinary detergents or wiped with a damp cloth.

Advantages of MDF panels

- Availability. Easy to find in most hardware stores or specialized markets.

- Low cost. The total cost of the purchased material will be less than most analogues.

- Ease of installation. The simplicity of design allows you to mount MDF panels quickly and without problems. Even a person without experience with the necessary tools can do this job.

- Presentable appearance. The appearance of the MDF panels looks extremely solid, especially the colors for expensive wood species.

- Additional thermal and sound insulation.

- Safe composition. Do not contain harmful substances to human health.

Disadvantages

- Fire hazardous. Made from wood components, panels can catch fire from exposure to flames.

- Poor moisture resistance. The damp indoor environment is not the best option for placing MDF panels. Long exposure to a humid environment negatively affects the structure of the material, it swells and bends.

Areas of use

MDF wall panels have a fairly wide area of use. Finishing material is suitable for decoration of living rooms and commercial premises. It is in demand with:

- wall decoration. Allows you to form a high-quality beautiful coating,

- production of interior doors,

- roof battens

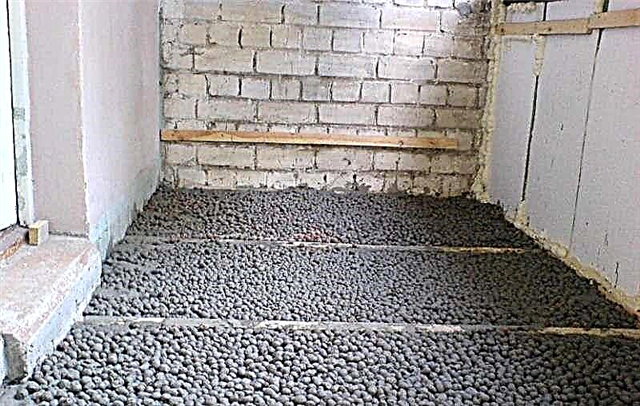

- the formation of the rough floor,

- decoration of the ceilings.

Types of MDF panels by production technology

The following modifications are distinguished, depending on the production technology used:

- Standard. The easiest option, low cost, as it does not have any additional features. It is used for decoration strictly in rooms without a sharp temperature difference.

- Moisture resistant. Processed with a special composition that is able to withstand the effects of moisture. It can be used in bathrooms and toilets, however, prolonged and direct exposure to water will still damage the panel.

Types of panels according to the method of design of the front part

The front part of MDF panels can be divided to a large extent, which creates a wealth of choice:

- Laminated. It is resistant to many factors: moisture, mechanical damage, etc. Obtained by applying a special layer on the surface of the panel.

- Veneered. A thin layer of wood is placed on the surface, which gives the product a beautiful structure.

- Cork. A special production technology allows you to cover the wall panel with a thin layer of cork. The resulting modification is very expensive, and does not always justify its use.

- decorative. Imitating natural stone, brick or tile.

Types of MDF panels by manufactured sizes

Before buying MDF panels, you need to familiarize yourself with its size. All manufacturers produce products with different dimensions, however, it is possible to note frequently encountered options.

For example, most often produce sheets with a length of 2600 mm, but you can find options from 2400 to 2700 mm. Width is also not a uniform value. Usually the value of this parameter is in the range of 150-900 mm. Some manufacturers produce sheets with a width of 1200 mm.

Thickness can vary several times. Most often, 3-9 mm thick panels are used during repairs, but even 60 mm options can be found on sale.

Dimensions

A wide variety of MDF panels led to their widespread use in construction. Under the various needs of the construction industry, panels with appropriate dimensions are produced. The dimensions and weight of the plates are unified and regulated by technical standards of production.

For wall cladding, wall panels with dimensions of 2.62 meters are produced. A number of manufacturers offer panels of 2.8 meters and 2.44 meters in length. Width corresponds to type from P-1 to P-5.

| P-1 | 100 mm |

| P-2 | 125 mm |

| P-3 | 150 mm |

| P-4 | 175 mm |

| P-5 | 250 mm |

MDF boards are available in length and width of 1.5 meters x 0.1-0.9 meters. The size of the slab depends on the surface texture - embossed, perforated and panels with imitation of natural stone reach a size of 2.8 by 2.07 meters. Square panels for decorative panels have other sizes - from 29x29 cm to 95x95 cm. The thickness of laminated and painted panels varies from 3 mm to 30 mm.

Veneer coating involves increasing the width of the panel in some cases up to 60 mm.

The weight of the panel depends on the size, presence of veneer or relief. To get an idea of the average weight of this finishing material, it is worth focusing on the weight of 16 kg of the panel with dimensions of 2.8 x 2.05 x 0.003 meters and the weight of 142 kg in dimensions of 2.8 x 2.05 x 0.028 meters. Thinner and lighter products are used for the ceiling, panels with a high coefficient of strength and resistance to mechanical stress are used for walls. If necessary, create sound insulation with the help of MDF finish, it is necessary to select the maximum thickness of the plate. Of course, the weight of this design, if the height of the room is large, will be significant.

Pay attention when calculating the weight of the cladding on the decor of the panel. Lamination and painting slightly increase weight. Veneer, relief increase this indicator. Perforation, on the contrary, reduces the mass of the structure. For smaller surfaces, panels or slabs of smaller sizes are chosen, since cuts will violate the decorative finish and create difficulties in sealing joints. Large areas are best designed with large-sized plates and panels.

Types of MDF panels by installation method

There are three popular types of MDF panels, depending on the installation method:

- Tile. This type of panel is the most popular, has clear dimensions and is well suited for stylish wall decoration. It differs from other types in a large number of options and a clear texture. There are square and rectangular variations.

- Lining. This styling option is most common. It is easy to use and the cheapest. The panels are mounted by connecting them using the grooves where the spike is inserted. The laying technology is very simple, so it can be done independently.

- Sheet. Unlike lining, this type of panel is much larger and does not have grooves for connection. Installation is done through the creation of decorative seams. They are created thanks to special elements. The positive point of using such MDF panels is a holistic pattern, created due to the large size.

Shades of various colors and textures

A big advantage in a wide selection of shades and textures of the panels. In most cases, the pattern imitates different varieties of wood.

MDF wall panels are made using the same technology, but the surface of such products may have different finishes. In this regard, the materials under consideration can be divided into several varieties:

- Veneered. In this case, natural veneer is used as a decorative finish. Thanks to such a coating, the product resembles a natural wooden massif by external signs and has a maximum cost among analogues.

- Laminated panels are considered one of the most sought after designs. The simplest embodiment of such products is considered to be gluing the surface with a melamine film. Such a material usually mimics the structure of wood; it is used to decorate walls. In some products, a high-gloss film can be applied to the surface during lamination to improve the appearance of the material. Such panels look exclusive and respectable.

- The corridor can be decorated with painted MDF panels. Here, a decorative coating is a layer of paint instead of simulating the texture of wood.

The products in question can be used to clad any of the rooms of the apartment with the exception of the bathroom. The surface of such products is significantly different from the unnatural appearance of plastic. The end user can choose for himself an acceptable design and size of the product, paying relatively little money for building materials.

And now pay attention to the dimensions of the product:

- The standard indicator of the length of the slab is 2.6 meters, although the dimensions of some materials may vary up or down - 2.4 or 2.7 meters, respectively.

- The width of the panel also varies significantly, for example, the MDF skirting board has a width of 15 centimeters, while the parameters of a conventional plate are within 90 centimeters, in some products 1.2 meters. The width of the material significantly affects its aesthetic functions. With an increase in this parameter, a person notices the presence of vertical seams, which further emphasize the texture of the product.

- Depending on the final destination, the panel thickness ranges from 3 millimeters to 3 centimeters. For veneered materials, this figure can reach up to 6 centimeters.

Making a choice of decorating elements, it is necessary to remember that the most delicate details have minimal strength indicators, therefore, they are used to finish the walls. Materials having a thickness of more than 1.2 centimeters are often used as an additional heat-insulating layer. By properties, such a heater replaces a brick wall with a thickness of 15 centimeters.

How to choose?

A wide variety of MDF panels makes you competently approach the choice of finishes for a particular room. It is necessary to take into account the temperature and humidity conditions in the room - for the exterior decoration of the loggia or kitchen you need to select moisture-resistant panels, and for facing the surfaces inside there are enough average indicators. The decor of the panels should also match the purpose of the room. In the decoration of walls and ceilings, it is better to adhere to one style of design.

MDF boards decorated with veneer will give the living room or office the necessary solidity. There is no increased humidity, so it is not necessary to splurge on moisture-resistant MDF, but noise protection is required, therefore, you should pay attention to this indicator when buying. Costly finishes emphasize the prosperity of the owners. The veneer of light oak or Italian walnut is an indispensable attribute of interiors designed in a classic style and fashionable minimalist design.

MDF tiles are used to decorate interior partitions that do not have entrance doors to create isolated zones in such transformer spaces. Partitions get the necessary massiveness when choosing panels of saturated tones. Such zoning provides adequate sound insulation. You can place a berth behind the partition from the panels, while the light from the kitchen will not interfere with relaxation. The high decorativeness of MDF boards makes an ordinary wall the main emphasis of the decor due to the beautiful noble color and interesting pattern of wood fibers.

To decorate the apartment, where the hall and the kitchen are combined, instead of interior partitions, a perforated MDF plate is installed, painted or laminated on both sides. Moreover, each side can have its own texture and color, corresponding to the rest of the decoration of its zone. The installation of perforated plates on the bedroom ceiling with spectacular lighting will be a real decoration of the interior. The chic elements bring a metallic finish and a combination with the pure white color of the rest of the finish.

For interior decoration of a summer residence or an attic in a country house, it is worth choosing inexpensive laminated or painted rack products. Owners without outside help will be able to sheathe the lining of the walls of the room.It is necessary to purchase material with increased moisture resistance for rooms not heated in winter, so that temperature drops and high humidity in the spring-autumn period do not deform MDF. The same requirement applies to the design of the apron in the kitchen. It is necessary to take care of the insulation of the finishing material from heating - MDF can ignite not only from an open flame, but also from strong heating.

In the children's room you can allow yourself to show imagination in choosing a picture and color, move away from stereotypes and create a bright and cheerful atmosphere instead of a boring traditional interior. MDF boards are well washed, this quality is very useful in a children's room. Do not pick up expensive facades made of natural or laminated veneer, give preference to bright glossy plates or slats. Doorways are painted in one of the colors of the panels or pick up cashing from the same material. Designers recommend paying attention to panels of suitable subjects: for boys - marine, for girls - fairy tales.

Popular manufacturers

Today, many companies around the world produce these products, however, not many can boast of good quality. Consider the rating of the best companies producing MDF panels:

- Swiss krono group. A large wood processing company that has representative offices and factories in many countries of the world. The products are of European quality at domestic prices.

- P&M Kaindl. Austrian company, one of the leaders in the production of MDF products. The plant has the most advanced equipment, allowing only high-quality products to be sold worldwide, including in our country.

- Sonae Industria. The company from Portugal is also one of the largest in the world. It has been producing MDF boards for almost 30 years. During this time, proved to be the best.

- LLC "Master and K". Domestic company, existing for more than 20 years. The high-quality products of this plant used are sold not only in Russia, but also in many countries of the world. The assortment of the company is constantly expanding.

How to fix wall MDF panels

Many homeowners do not know how to fix MDF panels to the wall. In practice, two popular methods are used: fixing products on a pre-aligned frame and mounting the material on liquid nails or another composition. When choosing a method, you must pay attention to the following:

- When using the crate, the curvature of the walls does not matter, the direction of the finishing plane will be determined by the elements of the frame.

- For use in wet rooms, a frame made of galvanized steel is suitable. Such products withstand moisture fluctuations and are not susceptible to corrosion.

- If it is necessary to lay insulation under the finish, the use of a crate will be an ideal option. Any heat-insulating material can be laid between the guide rails.

- Landing panels on glue is suitable for small rooms in which it is necessary to maintain maximum usable space.

Frame mounting

And now we will get acquainted with the method of laying MDF boards on the frame in more detail. First you need to make a crate for the walls, usually this design is made of a metal profile or a wooden beam of a certain section. When using wood, a square beam with a side length of 3 centimeters is chosen. Such a product should have a moisture content of not more than 15%. The material is additionally treated with an antiseptic and flame retardants, which interferes with the combustion and rotting process.

Next, they measure the walls with a construction tape. The length of the bars should be slightly less than the calculated values. With a horizontal arrangement of panels, the installation of the lathing is carried out in the vertical direction and vice versa. After the marking work, the dimensions are transferred to wooden products and raspilivanie bars. During such operations, the hacksaw should be located strictly perpendicular to the surface of the wood, which will prevent the formation of curved ends.

Guide rails are fixed to the surface using dowels (if the base is brick or concrete) or self-tapping screws (if there is a basic wooden surface). After that, in the intervals between the elements of the crate, insulating plates, for example, mineral wool, are laid. For fastening the finishing layer, you can use clasps for MDF panels, as well as self-tapping screws with dimensions of 3 * 20 millimeters, which are screwed into the grooves of the products or special nails with a thin hat. At the final stage of work, the connecting strips and the outer as well as the inner corners are fixed.

The device of the metal frame from the profiles is almost no different from the installation of a wooden crate. To begin with, wall guides are installed around the perimeter in the upper and lower parts of the building. Then the main profile is placed at a distance of 40-50 centimeters from each other. All guiding parts are fixed on the wall surface using self-tapping screws and suspensions, after which they begin laying the finish coating.

Glue mounting

As we have already said, gluing MDF panels to the base surface is most often used to decorate small rooms with even walls. At the initial stage of work, a thorough study of the base is carried out, defective areas are determined and measures are taken to seal cracks and chips. Sometimes the leveling process takes longer than finishing the wall.

After the surface is leveled and the solution has completely hardened, the plane must be treated with a deep penetration primer. This solution will increase the strength of the base, increase adhesion to the adhesive mixture. A similar composition is applied to the wall with a paint brush or roller, avoiding smudges. Now you need to cut the MDF panel with a jigsaw or hacksaw into pieces of the required size.

At the next stage of work, the necessary amount of glue is kneaded and the prepared solution is applied to the back surface of the panels. This substance is placed pointwise, and the places covered with glue should be as large as possible. Laying starts from the bottom of the wall.

At this stage, each element must be gently pressed against the wall and held in this state for several seconds. Similar work continues until the surface is completely covered. At the very end, the connecting strips and corners are attached, which are fixed to the surface using the same liquid nails or special glue.

Cost of MDF panels

For many developers, the issue of the cost of panels remains relevant. The price of the products in question will depend on the popularity of the manufacturer, as well as the overall dimensions of the plate. One of the most popular varieties is considered to be a decorative panel with dimensions of 2.6 * 0.2 meters. The price of such a product in construction stores ranges from 100 to 150 rubles apiece.

In size and shape

The size of wall panels directly depends on the manufacturer. Dimensions can vary over a wide range. The length is usually 2.4–2.7 m. The most popular are MDF panels with a length of 2.6 m, therefore, in the catalogs of most manufacturers there are such products.

Width is not unified. Usually 150–900 mm. Some companies may find sheet panels having a width of 1200 mm. Thickness is usually 3–9 mm. Although there are thicker products with a thickness of 60 mm.

Size can vary over a wide range

Size can vary over a wide range

Wall panels may take the form of:

- tiles. Elements have clearly defined boundaries. Allow beautifully designed walls. Presented in a large assortment. There is a choice of design options and textures. They are rectangular or square,

- lining. The most common option available. The joint groove - spike allows you to securely fix each element. Installation work can be done independently,

- sheet. Such MDF wall panels do not have grooves for connecting the elements, and they have a large width. During installation, decorative seams are formed using special elements. Allows you to complete a complete picture.

By the method of finishing

The appearance of MDF wall panels depends on the production technology used. Manufacturers offer products:

- veneeredwhich use natural veneer for decoration. Externally, this material is similar to a natural massif. Has the highest cost

- laminated. The most popular option. In the production process, the front surface is glued with a melamine film. Most often imitates an array, but a copy of any material is possible due to gluing with a glossy film,

- tintable. A coat of paint is applied to the surface of such MDF wall panels, giving the surface the desired color.

Appearance depends on the finishing method.

Appearance depends on the finishing method.By type of connection

The panels can be connected in various ways. It all depends on the characteristics of a particular material. The choice is:

- Thorn groove.

- "Groove-groove".

- Special profiles that ensure reliable fixation of elements relative to each other.

- No additional items. When installing lightweight wall panels on a leveled base with an adhesive method.

Performance characteristics

For the manufacture of MDF wall panels, sawdust is used, to which, to ensure the required characteristics, a certain amount of fastening and disinfecting materials is added: formaldehyde, which prevents decay, and special resins. The main parameters of the finished material should include:

- tensile strength 17–23 MPa, showing what pressure the panel can withstand once,

- humidity level about 3–10%,

- density affecting the strength characteristics of panels. Fluctuates within 600–850 kg / m ³. To label products with a low density (200-600 kg / m³), the abbreviation LDF is used. Products with a density of 600-850 kg / m³ are labeled HDF,

- high moisture resistance indicated by the manufacturer directly on the package,

- the presence of flame retardants that contribute to improving fire resistance.

Performance characteristics affect the life of the formed coating.

Performance characteristics affect the life of the formed coating.Advantages and disadvantages

The main advantages of MDF boards are:

- increased resistance to moisture,

- sufficient strength characteristics

- lack of negative impact on the environment,

- the possibility of finishing without preliminary preparation of the base with the frame method of installation. You can refuse preliminary puttying, priming, plastering, which significantly increase the cost of work,

- the minimum amount of waste and shavings, which allows to optimize the cost of purchasing finishing material,

- presentable appearance. Dust practically does not settle on the surface, which allows it to look perfect for a long time,

- the possibility of laying communications under the crate.

The disadvantages include:

- limited use in rooms with high humidity. Before starting installation work, all the edges are treated with a moisture-proof compound that prevents moisture from entering the MDF wall plates,

- high requirements for installation work. If the elements are incorrectly positioned inside, moisture begins to accumulate, causing deformation,

- low fire resistance.

Color solutions and design

Manufacturers offer decorative materials with different colors. The most popular are MDF wall plates imitating wood texture. Outwardly, they are almost indistinguishable from the array, but they are much cheaper and have less weight.

Many MDF wall plates mimic an array

Many MDF wall plates mimic an array

The surface of some panels is an imitation of animal skin or stone. Available in a choice of pattern and ornament. There are plain materials, there are painted in several colors. With their help, you can implement any non-standard design solution.

Imitation stone is very popular

Imitation stone is very popular

Leading manufacturers: choose quality

If you plan to purchase high-quality wall plates, we advise you to pay attention to the products of leading manufacturers. Such companies offer a decent finishing material from MDF, which can harmoniously fit into any interior. Positive feedback has earned the products:

- Swiss krono group. A large wood processing company has representative offices in many countries of the world. High-quality products that meet the requirements of European standards are also manufactured in Russia,

- P&M Kaindl. The Austrian manufacturer occupies a leading position among peers. The availability of modern equipment, high-quality raw materials and compliance with technological requirements make MDF boards from Austria in demand around the world,

- Sonae industries. One of the largest companies, located in Portugal, has been operating on the market for almost 30 years. Makes high-quality finishing material,

- LLC "Master and K". The domestic manufacturer has been manufacturing MDF wall panels for more than 20 years. Due to the high quality, the finishing material is sold not only in Russia, but also abroad.

Swiss krono group - products of excellent quality

Swiss krono group - products of excellent qualityChoosing MDF wall panels: general recommendations

To make the right choice:

- consider the purpose of the finish. Thin MDF panels having a thickness of less than 12 mm perform an exclusively decorative function. With their help, you can beautifully decorate the walls. Thicker products have good heat and sound insulation characteristics,

- make sure that there are certificates of conformity. It should reflect information on the composition of the material. In particular, the presence of formaldehyde and a toxic resin that is harmful to human health is unacceptable,

- Check all MDF panels from the purchased batch for external damage and defects. It is worth refusing to buy items that have cracks, bumps or other damage. Even if they are sold at a significant discount,

- make sure the uniformity of colors and uniformity of the formed layer. The presence of irregularities indicates a poor quality finishing material.

The choice of MDF wall plates should be taken with all responsibility

The choice of MDF wall plates should be taken with all responsibilityMDF panels in the interior: photos of interesting solutions

If you have not yet decided on the feasibility of purchasing MDF wall panels, we suggest that you look at the photos of already completed projects. You might want to use them as an idea for later implementation.

The material is relevant for the decoration of various rooms

The material is relevant for the decoration of various rooms

To the frame

With the frame method of installation, the crate is pre-mounted. Wooden elements are covered with drying oil, and then with an antiseptic. If the operation will be carried out in conditions of high humidity, antiseptic treatment is performed twice.

The crate is installed around the perimeter of the room. The installation procedure depends on the chosen direction of fixing the MDF panels. If the wall slats will be located vertically, the elements with which they will be mounted are mounted horizontally. Otherwise, vice versa.

Attention! In the process of collecting the crate, the spatial position of each element should be carefully verified. Otherwise, it will not be possible to form a perfectly even coating.

After mounting the battens, panels are attached. To correctly connect the parts, clamps are used - kleimers.With their help, each wall panel is attached to the frame. First, it is connected to the lamella, and then the Kleimer is hooked to the crate.

For fixing, special fasteners are used.

For fixing, special fasteners are used.

On glue

The glue method allows you to abandon the frame device. Fixing of MDF wall panels is carried out using adhesive composition. However, preliminary preparation of the base is required. Plaque is removed from the wall and each panel, all pollution. The base is carefully leveled. The presence of significant differences in height will lead to unreliable fixation of the elements.

Attention! When choosing the adhesive composition, you should focus on the colors of the selected MDF wall panels.

After fixing the elements should refuse to perform any work related to the base. You can resume the finish after the composition has completely dried. The time required for solidification depends on the manufacturer.

Installation on glue requires special preparation

Installation on glue requires special preparation

Operation and maintenance

Use a soft cloth or sponge to clean the MDF wall panels. Hard brushes should be discarded. Household chemicals should be designed to care for such surfaces.

Share your experiences with using MDF wall panels in the comments and opinions on their performance.