Almost any novice master who has minimal experience with level and hacksaw in wood is able to cope with the installation of an interior door. There are no special skills required. It is quite possible to install the door block in your home yourself. It is only necessary to correctly measure everything before installation, and during the assembly process to ensure that there are no distortions.

Necessary materials and tools

A large set of tools and supplies for installing a wooden interior door is not required. This is not a sewer, electrics or plumbing device in a private house. In the case of the door block, all consumables (anchor bolts, self-tapping screws, carnations, handles and awnings) are already included in the delivery package of the product. In addition, you need only assembly foam.

Installing the doors yourself is not so difficult, but nevertheless this work requires attention and certain skills.

To install the interior door, from the tools you will need:

- hacksaw with a small tooth,

- building level,

- tape measure with a pencil

- screwdriver (screwdriver),

- chisel,

- hammer.

You will also need small thin wooden pieces for struts so that the door does not jam after foaming. Foam in the air expands two to three times. So that the canvas and the jambs during its application do not lead, it will be necessary to first insert wedges in several places at the time of setting and hardening of the adhesive.

Step-by-step instruction

If the installed interior doors exactly fit the existing opening, it is recommended that they be installed at the final stage of the repair of the cottage or apartment. Then, when the ceiling is already whitewashed and the wallpaper is pasted. But if the doorway needs to be expanded, then to do this work is at the stage of rough finishing. Mud and dust when breaking walls forms a lot.

Step-by-step instructions for installing interior doors

Do-it-yourself installation of interior doors is done in six steps:

- Assembly box.

- Installation of loops.

- Canopy door leaf.

- Installation of the threshold and extras.

- Mounting platbands.

- Installation of door accessories (locks and handles).

Box assembly

When studying which pipes are better for water supply and easier to install, you have to consider many metal and plastic options. With door blocks for interiors is much simpler. Almost all of them are made of lumber. Plastic or aluminum structures in private homes are extremely rare. As a result, you only have to work with the installation of interior doors with wood, which is not so difficult.

Types of door frames

There are two ways to assemble a wooden door frame:

- a cut of the corners of the upper crossbar and vertical racks at 45 degrees,

- butt and butt joints without corner cuts.

The first option looks more elegant. However, the second is simpler in independent cutting. Only with it you need to be very careful when cutting the side on the upper crossbar so that the vertical bars stand evenly and without gaps. At the same time, it is recommended to choose the method of assembling the external frame of the interior door, depending on the interior design.

Required dimensions and tolerances for assembling the door frame

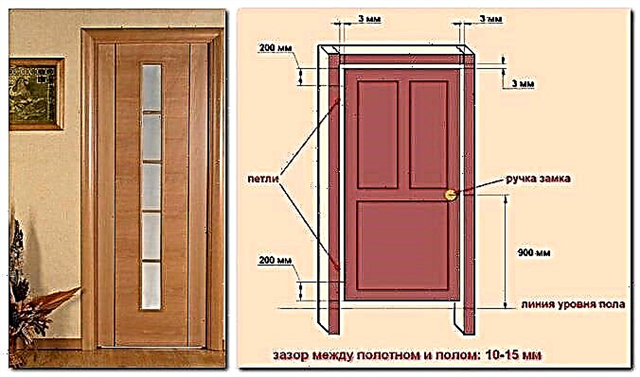

To prevent the canvas from sitting too tightly in the box, when trimming the crossbar, 3 mm additionally should be laid left and right. The fastening of horizontal and vertical parts is carried out in the corners from above by screws in the end of the racks outside. And so that when the screws are screwed in, the box bars do not crack, you must first drill into the holes with a thin drill (a millimeter thinner than fasteners).

At the same time, the supporting rack, where the hinges will be, should not be pulled tight to the end at this stage of the installation of the door. It should only be slightly fixed in place.

Hinge installation

The hinges are first hung on the canvas indented from above and from below 200–250 mm. Hinges at interior doors are overhead ("butterflies") and countersunk. The first ones are enough to attach to the end face with the inner small part and fix it with self-tapping screws. And for the second you have to pre-cut the grooves.

Necessary measurements for installation of loops

Next, the canvas is inserted into the box laid on the floor. And the marking of the mounting points of the loops on the racks is made. But first, between the end of the canvas and the details of the box, you need to insert pieces of wood (pieces of fiberboard) with a thickness of 3 mm, so that there are then gaps.

Then, the support strut, which is not completely tightened, is unscrewed from the crossbar and loops are screwed to it. And then it is put in place and finally fixed with screws.

Sealing gaps, holes and installing additional

Between the outer side of the block and the end of the wall it is allowed to leave a gap of 0.5 to 3 cm thick. But if the house is wooden, then this gap should be at least 1.5 cm in case of shrinkage of the log house.

Options for interior doors

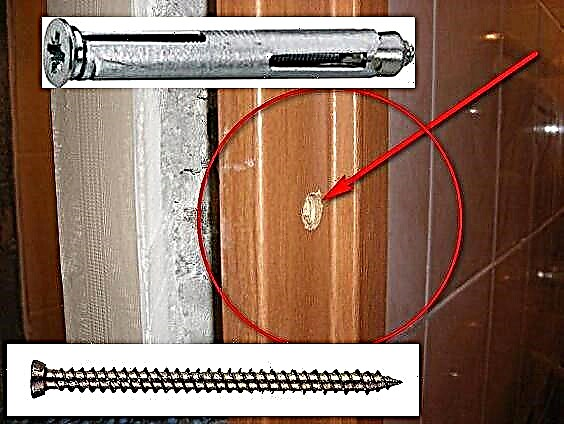

The box is fastened with anchor bolts, which are placed under the hinges and the key lock. To do this, first, in vertical posts on both sides, holes are drilled to the wall. Then the block is removed and the interior partition itself is already drilled. If you work with a drill without cleaning the box, there is a serious risk of accidentally damaging its decorative coating.

Also, the box can be fixed with metal suspensions. They are first screwed to the uprights, and then, after bending to the wall, they are attracted to it with self-tapping dowels.

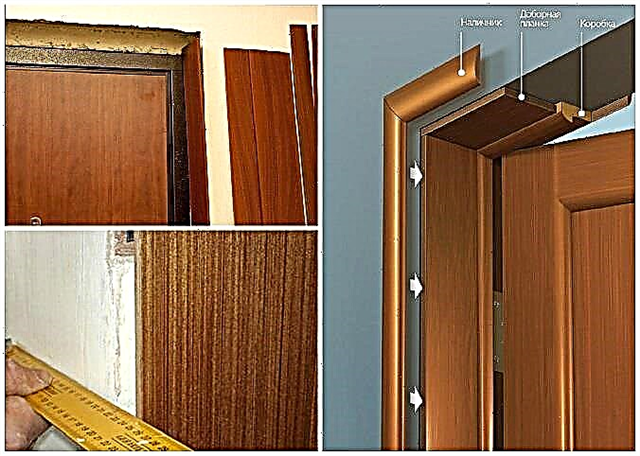

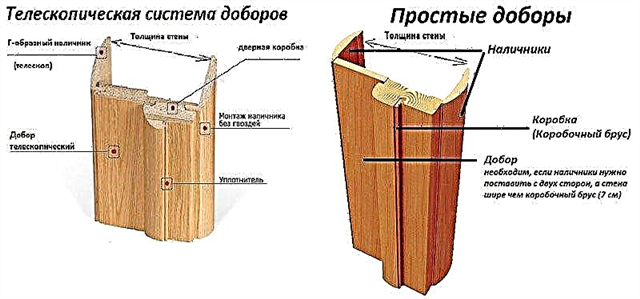

If the wall is thick, then you will need to install additional ones (false slopes, additional timber). The box has a so-called coverage area. This is the interior space and needs to be decorated. Extras are made from solid wood, fiberboard or MDF. After cutting to the required dimensions, you just need to attach them to the box and fasten to it with long screws. Then, along the entire perimeter of the opening, spacer wedges and a spacer in the middle are also placed under them.

Installation Instructions

All that remains is to spray the mounting foam and leave the unit closed for a while at rest. Continuing to install the interior door is recommended the next day. The foamed glue should completely harden and fix the door frame.

Setting the threshold and platbands

The threshold and platbands are installed after fixing the box with anchors and mounting foam. The first is a metal bar with holes under the dowel-screws. It is required to cut off the width of the opening, drill holes in the floor and “nail”.

Platbands for interior doors come in the form of:

They are fastened with the help of a lock connection ("tenon groove"), with nails or with glue. Trimming them in the upper corners of the door is made at 45 or 90 degrees. In this case, the joints of the crossbar and vertical slats should be made as dense as possible. The slightest bumps and errors during sawing will then be visible.

Options for arranging the threshold of interior doors

Installation of accessories for interior doors

At the end of the installation, locking hardware is installed. And usually for interior doors, a mortise product is selected two in one (handle + lock). Such a device can be rotary or push type. But in both cases the principle of work is the same.

Install the mortise handle as follows:

- Marking the canvas at a height of about a meter from the floor.

- A hole is drilled for fittings.

- A handle with pads (sockets) is put and bolted together.

- On the contrary, in the beam of the jamb, a groove is cut under the tongue and a reciprocal metal bar is placed.

Step-by-step instructions for installing a door arm

Drilling the hole is most correct to do with a crown of the appropriate diameter, so that it turns out even. And the counter on the box and the mounting plate on the canvas should be recessed so as not to interfere with the closing of the door.

Recommendations and Tips

To self-installation of interior doors did not end badly, you should:

- screw all the screws only after drilling thin holes under them, otherwise the beam and the blade can crack,

- install the unit strictly vertically (even if the slopes are curved or go at an angle),

- correctly dispense the mounting foam, a large amount of it can lead to skewing of the block,

- leave a gap of 10-15 mm between the canvas and the threshold to ensure natural ventilation.

Everything should be done carefully and without haste. Marking and cutting of wooden parts must be done only after two or three measurements. To remove an extra centimeter, and even more so to add, will not work here. It is possible to clean and prepare the drainage pump for dirty water for winter in a couple of hours. In order to install the door block according to the rules, it will take at least a day.

On the one hand, you need to carefully measure and prepare the walls, and on the other, do not forget about the time it takes for the foam to harden. The latter not only fills the voids, but also is an element of rigid fixation of the block in the opening, ensuring its resistance to external loads. You should not rush with installation and neglect the rules.

Door placement recommendations

If the opening is too high for the selected door, then you can close the empty space from above with the help of wooden bars and drywall. From above, they will be covered with wallpaper or other wall decor. If everything is done carefully, it will be difficult to distinguish the finish in this place.

Conclusion

The above instructions and tips should help you correctly install the door in your home without errors. To put the door block yourself, you do not need to have special knowledge and skills. It is not a metal-plastic or polypropylene pipe to mount. However, there are nuances in this installation. In this matter, the requirements of building codes should be strictly observed, otherwise the canvas will jam or it will not be able to stand exactly in the frame box.

Frequent door installation orders

Formation of seats with a slot mill for installing 2 detachable, non-universal hinges, interior latch, handles, mounting the door unit in a finished opening

Installation of doors with a height of 2000 mm Installation includes: Insert of 2 hinges, insert of handle / latch, assembly of door frame, installation of door unit, installation of door trim from 2 sides, mounting foam, fixing materials

Installation of a standard wooden sliding door: installation of a guide, installation of a roller mechanism, canopy of the canvas, adjustment of gaps

The installation of standard interior doors, including the assembly of the door frame, the insert of fittings, two hinges, the installation of platbands on both sides, the latch handles and the cleaning of construction waste from the apartment will be:

| Job | Description | Warranty | approximate cost |

| Job | Description | Warranty | approximate cost |

| Arches | Formation of seats with a slot mill for installing 2 detachable, non-universal hinges, interior latch, handles, mounting the door unit in a finished opening | 2 years | From 1100 rub. |

| Interior doors | Installation of doors with a height of 2000 mm Installation includes: Insert of 2 hinges, insert of handle / latch, assembly of door frame, installation of door unit, installation of door trim from 2 sides, mounting foam, fixing materials | 2 years | From 1300 rub. |

| Sliding doors. | Installation of a standard wooden sliding door: installation of a guide, installation of a roller mechanism, canopy of the canvas, adjustment of gaps | 2 years | From 1300 rub. |

| Door installation. | The installation of standard interior doors, including the assembly of the door frame, the insert of fittings, two hinges, the installation of platbands on both sides, the latch handles and the cleaning of construction waste from the apartment will be: | 2 years | From 900 rub. |

The Myguru company offers services in professional installation of interior doors to an apartment in Balashikha at affordable prices. Many years of experience of our masters, the availability of professional tools and high-quality accessories guarantee reliability and durability.

Depending on your wishes, we are ready to install doors in standard openings made of brick, reinforced concrete, aerated concrete or cinder block in strict accordance with all standards and GOSTs with a guarantee of up to 2 years. If the aperture is too large, it can be sealed (laying with a brick, foaming or use of extras). In the presence of a narrow passage, its expansion is possible. Unlike the basic ones, all additional services are paid separately, but are agreed in advance and are inexpensive.

High professionalism of employees allows the installation of interior doors of any kind, size and name. You can order the installation of paintings economy and premium. You should contact us if you want to supply the following types:

- Sliding

- Swing

- "Book",

- Coupe

- Bivalve or single leaf,

- Portals

How is the installation of the interior door to the apartment

The technology for installing an interior or front door consists of several stages. Cooperation begins with the departure of a specialist at home. He will inspect the front of work and ask questions of interest:

- Do you need to pre-dismantle the old canvas?

- Is a new box required to assemble or can an existing one be used?

- Is it necessary to expand the existing opening or bookmark it, is reinforcement required?

- What type of additional components will be required (including transoms, slopes, platbands, thresholds, latches, hinges)?

The master brings the tool and materials with him, which gives him the opportunity to immediately proceed directly to the installation process itself, which includes:

- Removing the old box with the removal of excess plaster from the walls,

- Installation of a new unit with its fixing to the wall using anchors,

- Attaching a new web with grease hinges. After installation, special grease residues are removed with rags,

- If the openings between the wall and the box are small, they foam (large ones are covered with building mixtures).

- The door is sheathed by slopes (most often from drywall), platbands are glued. At this stage also usually occurs lock insert.

- The last stage is the cleaning of the premises after work and the delivery of work to the client.

On average, installing one door will take about an hour. Installation time is agreed in advance.

Why is it profitable to order door installation from us?

In addition to the fixed affordable prices for our services in Balashikha, indicated in the price list, we offer our customers a large number of other pleasant bonuses. It is beneficial to cooperate with us, because we carry out our work efficiently and give a warranty card for two years on it.

Another nice bonus is a free consultation on proper operation after installation. Still have questions - call right now?

Dimensions and equipment

By the method of opening the doors are folding, sliding and swinging. The latter are the most popular, because structurally they are the simplest and fairly easy to install. They are presented in a large number of modifications. By the method of opening, the following are distinguished:

- bivalve and single leaf,

- left and right.

The most common sizes of interior doors are 710, 810, 910 and 1010 mm. Bivalves - 1340, 1540 and 1840 mm. The standard height of the doorway is 2055-2060 mm, but in fact it may differ upwards.

Of the basic materials you will need a door leaf, a box and platbands.

Of the accessories - hinges, handle, rotary lock and built-in lock mechanism.If the opening is deep (in the load-bearing wall), then extras may be required.

Materials and Tools

The installation of doors begins with the preparation of the tool. For installation work you will need:

- To level the door, you need a plumb line and level. For measurements, as well as marking, use a tape measure with a pencil.

- The process of assembling and installing interior doors includes the final trim in platbands, and, if necessary, in additions. A hacksaw with small teeth and a miter box are useful for cutting slats.

- A power tool needs a drill with a set of drills for concrete and wood, as well as a screwdriver.

- It is easier to make selections for fittings with a milling cutter, but in the absence of a tool you can get by with a chisel with a hammer.

Of the materials used are self-tapping screws, mounting foam, as well as many wooden wedges of different thicknesses for struts. Immediately you need to decide how to put the interior doors so that the fasteners are not visible.

If preference is given to flush mounting, suspensions are additionally purchased. You can fix the ore with anchors. To drown hats in secret openings, to putty, and to paint over from above.

Two ways to install the box

Open way provides for fixing the interior door box with anchors. The frame is inserted into the opening. Expose vertically and horizontally. All measurements are carried out by level, as well as by a plumb line. Observing a gap of 10 to 40 mm, wooden wedges are driven in between the box and the walls. By tamping or loosening the spacers, they achieve perfect evenness of the frame.

From the inside of the box, increments of 50-60 cm are drilled through holes with countersunk holes. In the wall, holes are drilled on concrete. The anchors are screwed so that the hat disappears inside a secret sampling. After a level check, the gap between the wall and the frame is blown with foam. Secret holes are puttied and then painted over.

Second closed way installation of the box involves the use of suspensions used in the manufacture of the frame for drywall, or a special installation system. The metal strip is screwed to the wrong side of the frame with screws. The box is inserted into the interior opening, wedged with wooden wedges, the suspension petals are bent onto the wall, fixing with screws with plastic dowels.

Installing an extension

When mounting the door unit in a deep interior opening, the frame is not able to close the entire wall. If the width of the box is not enough, then add. Decorative strips are installed on the longitudinal groove of the frame, previously lubricating the lock with glue. If the door frame does not provide a lock for extensions, the strips are fixed through secret holes with self-tapping screws. The optimal fastener pitch is 60 cm.

Door leaf installation

Before installing the door, the canvas is equipped with fittings. On the market there are canopies of different types and colors. The place for their fastening is determined even before the installation of the box. For interior sashes, the installation of butterfly canopies that do not require a tie is popular.

Two hinges are installed on a light sash, stepping back from above and below 25 cm. A heavy canvas is reinforced in the center by a third canopy. With the open method of fixing the box, the anchors are positioned so that they do not interfere with the screws to fasten the hinges. If the installation of interior doors was carried out in a hidden way on suspensions, the problem with the location of the fasteners disappears.

The gap between the end of the sash and the hinge post of the frame should be 6 mm. First mark the place for mounting on the end of the sash. Under the mounting plate of the loop, a recess is selected with a chisel. The canopies are screwed with screws.

The door leaf along with the hinges are inserted into the box. The sash is bursting open with wedges so that gaps form around the perimeter. On the loop stand mark the places for sampling the recesses. The canvas is removed from the frame, a recess is selected with a chisel, then the second halves of the canopies are screwed.

The handle with the lock is installed at a height of 90 cm from the floor. The housing of the locking fittings is applied to the sash at a measured height. Pencil mark the location of the pen, outline the boundaries of the castle. At the end of the canvas with drills or a chisel, a depression is chosen. For the handle, a through hole is drilled. The nest is varnished, a lock is installed, the housing is fixed with self-tapping screws, and then the handles are inserted. On the rack of the box opposite the lock, they make a selection, put the counter plate of the locking hardware.

To install the door with your own hands without defects, the process of hanging the sash is carried out after the hardening of the foam.

Fixing platbands

The final installation of the door unit is the fastening of the platbands. Decorative slats are placed on both sides of the interior opening. Platbands sell wooden, plastic or MDF. The shape is simple flat, with a bevel or curly. Platbands are attached to the end of the interior box with a lock connection, screwed with screws or nailed. The strips can be glued, but the adjacent wall should be perfectly flat, finished with a durable lining.

To perform a simple installation of door trim, first attach a horizontal level bar. The edges are pre-sawed at an angle of 45 °. Vertical slats are installed from the floor. Top mark the cut line at a similar angle. The joint is made as tight as possible. In the case of a gap, putty is used. After solidification, blemishes are painted over.

Platbands can be docked at right angles. The upper bar is wound between vertical elements or laid on top of the end.

Emphasis

The swinging interior sash that opens on the run by the children hits the wall with its handles. The decorative finish deteriorates and even the plaster streams. The installation of a door stop helps prevent the door from opening completely.

The emphasis is a barrel with a rubber nozzle. A limiter is installed after mounting the door unit and all finishing work. The sash is opened to the desired position. The location of the stop is marked on the floor. Drill a hole with an electric drill, drive in the fixing screw and clamp the stop.

How to change the canvas?

Often during the repair only replacement of the door leaf is required. The procedure is much easier than installing an interior door from scratch.

- The old canvas is removed from the hinges. Awnings usually consist of two split halves. To remove the interior sash, it is enough to pry it open with the bottom in the open state. If the hinge pin is inserted on top, the web will not be removed. First, a screwdriver is inserted under the head of the rod, then with a hammer blow it is knocked out of the socket. Dismantling starts from the bottom loop. After removing the rods, the sash can be easily removed.

- Two canvases are compared in size, stacked on top of each other. If the new fold is larger than the old, mark the boundaries with a pencil. Excess areas are cut with a hand circular saw. Slices are adjusted with a planer, processed with a grinder.

- A fitted door leaf is equipped with hinges, a lock, a handle.

- Hinges are in the reverse order.

If a new blade has been customized, the cut points must be masked. Paint and varnish material select close in color or completely repaint the entire canvas.

Interior doors can be divided into several types

On the market, manufacturers of door structures offer a fairly wide range. Ready-made interior doors can be made of different materials. The most common types of materials are: fiberboard, MDF, natural wood.

1. Fiberboard - door: the frame is made of wood, and sheathed with fiberboard sheets with lamination. The advantages of such doors include: low cost relative to other types, low weight, which makes it possible to deliver them from the point of sale to the house on their own, ease of installation. Given these points, they are popular among buyers, so their wide range is most often presented in stores.

Of the minuses, the low strength of the fiberboard itself can be noted, because of which the door breaks and becomes unusable quite easily, poor resistance to humidity, the door can twist. Therefore, we do not recommend its installation in bathrooms with a weak exhaust, this material loves dry rooms.

Below, we will consider the step-by-step installation of interior doors with your own hands.

2. MDF - doorsthat are made from this type of material are the most suitable option when choosing a ratio of quality and price. The obvious advantages compared to MDF doors are high strength and resistance to moisture, a higher level of sound insulation. The cost of such a door is several times higher than the doors of fiberboard.

Photos - Models of MDF doors

3. Natural wood - interior doors made of such material are the most durable. Their price directly depends on what kind of wood was used for their production. Doors made of precious wood are used for installation in rooms with an author's design, they fit perfectly into the classic interior. The width of the interior doors is selected according to the size of your opening.

The list of interior doors by types can be supplemented with all-glass doors, metal-plastic, steel, but these types are not very popular among the general population, therefore they are not included in the article for a detailed description.

Types of door frames of interior doors

The correct interior door should be in a reliable box for the door, because its quality will depend on how long the door will last, as well as the design of the doorway of your room. Door frames can be divided into three main types.

1. Fiberboard box. It looks pretty decent, but when choosing a box of this material, the strength of the whole structure is in question. The middle of the plank box bends from its weight, not to mention the possible deflections from the weight of the door leaf itself. Since the main components in the composition of fiberboard, in simple terms, are glue and paper, it must be borne in mind that they are very fragile and not durable. They are not recommended to hang doors made of wood and MDF because of their heavy weight.

2. Raw Wood Box. The cost is at the level of fiberboard boxes, but unlike the latter, boxes made of dry profiled timber have higher strength. Therefore, when choosing between fiberboard and raw wood boxes, we recommend choosing the latter. It is also necessary to consider that you will need additional materials for the final decoration of the box.

Photo - Raw wood box

3. Laminated wood box. It does not require a final finish, as it is already laminated with paper. And here there is one important point, when choosing such a box, the quality of the lamination is very important. If thin paper was used for this, there is a high probability of occurrence of scuffs, scratches, cracks, the coating loses its appearance. Perhaps a better option would be a box of raw wood with self-finishing and painting.

Photo - Laminated wooden box

Also, the entire doorway of the interior door may require additional processing after installing the doors. Everything will whistle from your opening, its size, the location of the door in it, the interior of the room.

For such processing, you can use the additional bar and platbands. The necessary kits can be bought at the store. We recommend that you determine their need after the final installation of the door, in order to understand what kind of final decoration you need. After all, the purchase of additional materials is an additional cost, which in the end may be unnecessary.

When installing the interior door, you will definitely need accessories. Read about the selection of interior handles and their installation.

Step 2. We determine the scheme for fixing the box in the doorway of the interior door.

The figure shows the fastener diagram of the door frame in the opening. As you can see, the interior door (2) is installed in the box (1), which is fixed in the opening on the screws (3). Between the wall and the box we blow foam (4). The process is as follows: install the box in the opening, fix it to the wall, foam.

Photo - Disassembled door frame and door before installation

If after installing the door it is impossible to hide its doors in the floor, for convenience, choose a box without a U-shaped door. It does not have a lower crossbar, so there will simply be nothing to stop you from walking.

Step 3. Assembling the door frame.

Loops should be attached to the purchased box. The door should have a cutout for the handle, as well as under the door lock of the interior door. We begin the assembly of the door frame. It is necessary to connect all parts of the box together and adjust to the size of the opening. Factory length usually comes with a margin of 5 cm.

The surest option is not to make a mistake - assembling the parts on the floor as they should be in the doorway. Particular attention must be paid to the metal bases of the hinges, they must stick up so that the door can be hung on top of them.

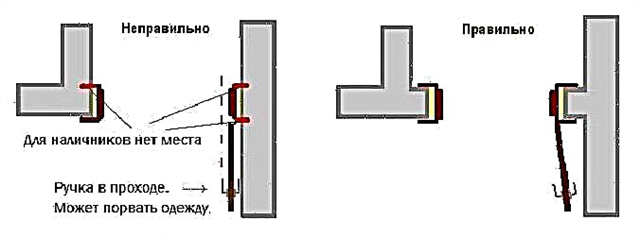

Choose the opening side depending on the rooms between which the doors are installed. From small rooms, such as a bathroom, pantry, it is better to open the doors outside, from large rooms to the corridor - to the inside.

Photo - The correct position of the end plates

We attach the upper bar to the screws. End plates (1) must lie in a line. If there is no line, then the bar lies incorrectly and needs to be deployed.

Photo - Screws to tighten after preliminary drilling

Given the structure of the fiberboard and the characteristics of its strength, in the box, before screwing in the screws with a base diameter of 3.5 mm, it is necessary to drill holes with a drill on a tree with a diameter of 3 mm. We carry out this action so that our box does not crack during the assembly process. For the same reason, the fastening points of the screws should be closer to the center, away from edges and corners.

Photos - Assembled box

Four screws will be enough for fixing the bar, two on each side.

If the door lies horizontally on the floor, put a soft cloth under it, so you will reduce the likelihood of damage to the laminated layer.

Photo - Factory stock box

The factory stock of the box (protruding edge) will be cut. To fit the box, accurately measure the dimensions of the doorway of the interior door. And we transfer it to the door frame, taking into account the gap minus 1-2 cm from all sides for the possibility of foaming. We recommend several times to double-check yourself for the size of the structure.

Photo - Measurement of the height of the opening Photo - Cut line of the excess part of the box

Protruding excess should be cut off with a hand saw. It is advisable not to use an automatic saw to avoid damage to the coating.

Photo - Cutting off excess with a hand saw

As a result of all the manipulations we get a U-shaped door frame, ready for installation in the doorway of the interior door.

Photo - Complete wooden box

Step 4. Installing the box in the opening.

We put the box in the doorway. Level by level. We verify the correctness and evenness of the assembly of the box by hanging the door on the hinges and closing it.

Photo - Checking the position of the box level Photo - Drill diameter 4 mm on wood

The box installed in the opening must be fixed with screws. We remove the end decoration strip and drill 7-8 through holes on each side. The distance between the holes is 25-30 cm.

Photos - Drilled box

A wood drill is not designed to drill walls; they only drill a fiberboard box. After that, we again check the position of the box using the level, since during the drilling process it could shift. If there are no changes, we begin to drill the wall.Using a thin drill on concrete with a diameter of 4 mm, through the holes in the box, we mark the wall. It is impossible to completely drill the wall through the duct, since it can be damaged. The diameter of the hole is 4 mm, if you make more, then the caps of the screws will fall out. Next, we remove the box from the opening and begin to make holes using a drill with a diameter of 6 mm. If the wall is brick, the holes for installation should be in a solid brick, and not in a masonry joint, in which the dowels are very poorly kept.

Photo - Drilled brick wall Photo - Dowels in solid brick Photo - Self-tapping screws for quick installation - on the left, wood screws - on the right.

Dowels are mounted in the finished holes. We fix the box in the wall using self-tapping screws. For convenience, you can use a screwdriver or drill with a nozzle under the head of the screw. Do not completely screw the screws in, the box can bend. Lining of wedges is possible to avoid deflection. To check the evenness and the absence of distortions, in the process of screwing in the screws, additionally check the box by level.

At the end of the installation, the box is checked from the side of the room using the level.

Photo - Checking the box by level

Step 5. Installing the door on the hinges.

How to put an interior door? Just put the door on the hinges

If this is a fiberboard door, given its weight, this can be done alone. After installing it, try to open and close. In the closed position, the gaps between the box and the door should be about 3 mm.

Photos - Check for gaps between the box and the door Photos - Closing and opening the door - easy, without distortions

The lock is inserted into the interior door. And also the installation of the handle.

Step 6. Filling the joints with foam.

An important step is to fill the gap between the wall and the duct with foam. It must be carried out with the door installed. In the process of drying, the foam increases its volume. If you go too far with its quantity, it can pry the screws, bend the box and the door cannot be closed. You will have to cut everything and start the installation again.

Gaps between the box and the door for the time of foaming must be laid with something.

Photo - Cardboard in the gap between the door and the box during foaming

Foaming seams is the most simple job. The vertical seam is filled from the bottom. You need to be careful about the volume of filling. Foam is able to increase its volume when dried. Therefore, it is necessary to fill the third part of the space between the door frame and the doorway of the interior door. In case of overspending, damage to both the box and the structure as a whole is possible, since foam can get on the front of the box and door and ruin their appearance. Full hardening of the foam occurs within 24 hours, the required temperature of 20 degrees.

Photo - Foam is applied to one third of the volume Photo - Interior door after installation

Step 7. Finishing the doorways.

After installing the interior doors, doorways require decoration. Depending on the width of the opening, as well as the type of door frame and door installed, it is necessary to choose the type of finish for the opening.

If the wall is thin, for example, the door to the bathroom, and the width of the wall is equal to the width of the door frame, finishing can be done using platbands (1). This is the easiest option. The purchased kit is attached on both sides of the box, closing the foamy seam. Wooden platbands without processing are fixed with screws, and then only painted. Laminated platbands fasten with nails without a hat or screws with caps.

Photo - Finishing a thin opening with platbands Photo - Finishing a wide opening with platbands and an additional level

Finishing of wide doorways of the interior door is possible with platbands (1) and additional strip (2). The latter can be cut to the required width. Attached to the wall with building silicone. Platbands and planks may differ from the color of the door. Contrasting solutions are quite relevant. If you still have questions, then we will consider in more detail the installation of platbands for interior doors.

Photo - Finishing a wide opening with plaster

If a door frame is installed in wood, a possible option of finishing may be slope plaster (1). Cement and sand plaster favorably emphasize your choice of doors made of wood. But it is not recommended for boxes made of fiberboard, as they are not compatible with the high humidity of the materials used for plastering.

Step-by-step installation of interior doors, not counting the preparation time, will take about three hours.

Consumables and tools

All that is needed for self-installation of an interior door is indicated below:

- hacksaw or saw,

- chisel,

- miter box

- building level,

- Phillips screwdriver or screwdriver,

- roulette of at least 3 m,

- polyurethane foam,

- hammer,

- dowels and screws,

- pencil,

- sealing tape

- spirit level - short (50 cm) and long (180 cm),

- universal screws

- knife,

- elbow

- wedges - wooden or plastic,

- nails are finishing.

Step-by-step installation of interior doors

How to install a single-leaf interior door so that it stands evenly and easily closes? The procedure is as follows:

- To dismantle the old door and prepare the opening.

- Assemble the door frame. The components must be laid out in the proper order, taking into account the direction in which the web will open.

- The upper bar of the box to connect with the ends of its two racks. You can use nails or screws.

- Install awnings.

- Install the box. The frame, which was assembled earlier, is placed in the opening, and then put up in a vertical and horizontal position using wedges.

- Hang a door. The hinge rack of the box must be fixed to the wall with screws, and then hang the canvas on the hinges.

- Secure the second post to the wall with screws. Then, on the sash, you need to check the gaps between the box and the edge of the canvas to prevent the formation of cracks. In a situation where a threshold is provided, it must be attached to the floor surface. Then foam mounting slots between the box and the edges of the opening.

- Insert the handle, lock and install platbands. Now we will analyze the technology of work taking into account the requirements of GOST and SNiP step by step.

Step 1: Assembling the door frame

A door frame is a frame made up of beams. Installation boxes can be made in a U-shaped or rectangular shape. The latter case is applicable when installing doors in the bathroom or toilet. The U-shaped form is usually used in all other cases when there is no threshold.

Cutting and connection methods

Manufacturers most often produce ready-made pieces for a box beam, which must be connected with each other with screws. If you plan independent work, then the best solution is to assemble the box according to the door leaf. To do this, the door is laid on a flat floor, after which the box parts are cut during the subsequent layout.

There are two ways to connect the details of the box:

- Washed down the lintels and racks at an angle of 45 °. For those who did not have much experience in carpentry, this method will be difficult to use. The parts themselves are connected using self-tapping screws. For them, you need to make holes perpendicular to the cut. Holes must be made in advance so as not to spoil the workpiece.

- He washed down at a right angle. To do this, it will be enough to use a hacksaw with small teeth. To determine the size of the bar vertically, you need to take the height of the canvas and add 3 mm to it to the bottom and top, provided that a threshold is planned in the doorway. If it is not there, you need to leave about 1 cm from the bottom. The ceiling will be fastened with two screws to a vertical stand.

It is important to remember - the second method is the only possible one in case of sawing a bar for the threshold.

It is very important during installation to check all the gaps between the box and the canvas - there should be 3 mm on all sides. If a U-shaped box is installed, it is necessary to maintain a gap of 1 cm between the floor surface and the door edge from the bottom.

Connection box elements

All racks prepared in advance, as well as the upper crossbar, should eventually be combined and pulled together with 6 cm long self-tapping screws. At least 3 self-tapping screws should be used for one joint.

To achieve a normal connection density from one of the elements of the box, you need to remove part of the quarter using a chisel or a hacksaw. The length of the part to be removed should approximately equal the thickness of the bar that is adjacent to the part.

Doing a Quarter Flush

Completed connection at 45 degrees

If the door size is much smaller than the opening, then installation should be carried out according to the following scheme with a lintel over the entire width of the opening.

Step 3: Installing the box and hanging the web

The box must be installed in a pre-prepared opening. The stand with the hinges must be aligned first with a plumb line or level. It is necessary to check it from all sides. Then the upper crossbar and the rack must be opened with wedges. The stand will be exposed only when it takes upright position.

Next, wedge the second rack. Be sure to check the horizontal part of the box.

The old way - side racks should be drilled through. To do this, holes for dowels are initially made in the wall. The box must be attached to the wall with self-tapping screws with a length of at least 150 mm.

Old way fasteners

In order to fix the box in the opening in a hidden way, you can use metal plates, which are usually used to install drywall structures. Most often, such plates are used together with anchors. In this case, it is worth choosing the number of fasteners in accordance with the expected load.

It looks like a mount

The use of such plates is a non-standard method and is possible only in the absence of a fine finish. It is recommended to grind a section of the wall in order to subsequently putty the fasteners.

It remains to hang the door on the frame. After that, you need to carry out the final adjustment of the box. Then the rack for the castle should be fitted under the door so that it does not protrude beyond the wall. It is worth remembering that to preserve the integrity of the box and the blade, you must first drill several holes for the screws.

Step 4: Foaming

After fixing the canvas, you need to foam the slots between the box and the edges of the opening. Foam should be fed gently, in layers, with the feed being made from above so that it does not protrude outward. Then the door will have to be closed and for a certain time not to touch it, so that the foam dries. The approximate drying time is 1 day.

If the composition accidentally gets on the canvas, immediately remove it with a clean, dry cloth, dried fragments are cleaned using effective methods of removing the mounting foam from the doors.

Step 5: Installing the lock and handles in the door leaf

The most popular today are handles with a built-in lock. The procedure is as follows:

- Mark a meter from the floor. The handle mechanism must be applied so that a mark is visible from above in the hole.

- Drill holes in the blade from the end. After that, the edges of the holes should be cut off with a chisel to even the hole.

- Insert the mechanism into the hole. In this case, the lock must be aligned, and then fixed with self-tapping screws. The strap on the lock should be encircled with a pencil for cutting veneer, then the mechanism should be removed. According to the intended contour, you need to select a site for determining the thickness of the keyhole. This is done using a chisel.

- Drill holes for latches and handles. It is necessary to attach the lock to the canvas from different sides, align it and mark it. The holes should be made on both sides and at the same time they should not be through.

- Remove the resulting chips and install the handles.

It is important to remember that you should not use the screws that come with the handle in the kit. They are made of non-solid metal, as a result of which they quickly fail. It is worth using high-quality red-hot self-tapping screws. Read detailed step-by-step instructions for installing the lock and handle on the interior door.

Step 6: Installing Trims

An extension is a strip about 2 meters long, 250 mm wide, and no more than 3 cm thick. The strip should be used during the installation of interior doors if the wall is thicker than the door frame.

The beam for the box is made in a standard width of about 70 mm. It can be expanded according to the thickness of the opening by adding. This will more clearly combine the box and the walls. On a bar there is a groove for a level. First you need to measure the distance to the edge of the wall, starting from the depth of the groove.

The add-on can be installed in various ways:

- in the groove in the box

- with groove cutting in the absence of finished,

- attaching the extension from the inside of the beam in the absence of a groove, the box is installed with the extension,

- fastening of a good in the form of "P",

- if the extension is not too wide and there is no groove in the box, the bar should be drilled and screwed to the box.

The plank is sawn into several parts with a circular to get several add-ons of the required dimensions. You need to cook one short bar and two vertical ones. Read our simple step-by-step installation instructions for installing an interior door.

Step 7: Fixing the platbands

During installation of platbands, the box should be located at a level with an opening on the front side. To connect the platbands, you must first attach the vertical bar to the box and put a mark higher by 0.5 cm, stepping back from the crossbar of the box. This mark will act as the edge for the slice. In the same way, you need to mark the slice on the other side.

Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.