Bulk floor crack repair. Bulk flooring is one of the most common types of floor leveling in a room. If the technology was broken during the pouring of the mixture, various kinds of defects may occur. This article will examine the question of whether cracks in the bulk floor need to be closed and why the bulk floor is cracking and how to remove cracks.

Cracked floor

Cracked floor

Improper preparation of the base for the bulk floor

Incomplete preparation of the base without fail will lead to deformation of the final coating. The base must be well dried and free from all kinds of dirt and dust.

If oil stains or grease stains are present, they should be eliminated. And also the concrete surface must be pre-ground. This must be done to eliminate unevenness of the surface, because on uneven floors can not be poured bulk floors. Filling of a bulk floor is carried out exclusively on the dried and leveled surface.

If a leveling screed was made, then before laying the floor you will need to wait at least 25 days until the concrete has completely dried. If you neglect this rule and fill the bulk floor earlier, then the moisture released by concrete will lead to swelling of the surface, and cracks in the bulk floor will also form.

Features of bulk mixtures

A dry mortar for leveling the floor consists of several components:

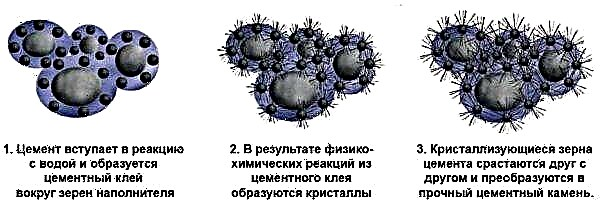

- Binder (cement and / or gypsum), which, after mixing with water, gradually hardens and gains strength. If the first process begins in 30-40 minutes and lasts 3-8 hours, then the second continues for more than 28 days,

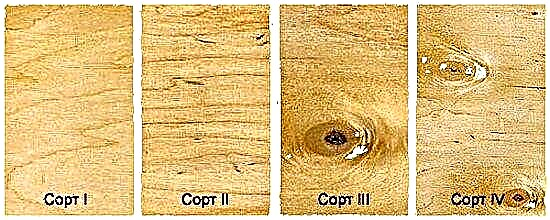

- Mineral fillercreating a kind of "frame" of the bulk coating. The fraction (grain size) used in the mixture determines the permissible coating thickness and the level of compression loads,

- Modifying additiveswith the help of which some characteristics of the solution are improved (elasticity, flowability, peel strength, kink, frost resistance, etc.).

Each of the elements requires specific working conditions. For example, cement needs a strictly dosed amount of water to start physicochemical reactions, modifying and plasticizing additives - a certain temperature and humidity regime, etc.

That is why every serious manufacturer conducts laboratory tests, selects the recipe, and looks for the best application options. After obtaining the necessary information, the technologists write detailed instructions for working with the bulk floor. Moreover, it is understandable to both professionals and inexperienced "homemade". And, of course, printed on every package.

The process of forming a bulk floor includes three stages:

- Substrate preparation (testing for strength, absorbency and evenness, cleaning, partial leveling, priming).

- Mixing the solution.

- Pouring the mixture.

Compliance with the instructions at each stage is very important, otherwise the result will not please you.

Has the bulk floor cracked? Looking for the causes of defects

The solution is worked out, the waiting time has passed, but the result does not meet the expectations. Do not immediately blame the seller and the manufacturer for slipping a poor-quality product. Practice shows: in 90% of cases, non-compliance with the basic conditions for preparing the base, violation of dosages, climatic requirements and deadlines - these are the main reasons why the bulk floor is cracking.

What to do? Elimination of deficiencies begins with the identification of errors. Let's start with the first stage - preparing the foundation.

Base strength

In accordance with SNiP 2.03.13-88 (SP 29.13330.2011), this indicator for concrete screed should be from 15 MPa (150 kgf / cm 2) and higher. Problems with the strength parameter may arise due to:

- Excess water in concrete or cement-sand mixture - screed separation occurs, the drying process and the set of strength are delayed,

- Cement of too low grade or poor quality - the underlying layer will quickly begin to collapse,

- Sand too fine or unwashed,

- Rapid withdrawal of water from the screed - the top layer will turn out to be fragile, loose.

Screed made of low-quality concrete.

After pouring onto a base that does not meet the standards, a stronger leveling mass “tears off” a weak surface layer. Cracks and exfoliated areas appear within a few hours.

It is not difficult to check the strength - try to scratch the floor with a nail or hit with a hammer. If the base does not meet the requirements of the standards, it will easily crumble, crumple heavily.

Evenness of foundation

Checking the evenness of the base.

This group includes two indicators - the level of differences and the presence on the surface of pits, cavities, protrusions and other defects.

Self-leveling floors are used to smooth the floor to a state close to ideal, that is, 2 mm for every 2 linear meters of the floor (SNiP 3.04.01-87 / SP 71.13330.2011). And in order to calculate the thickness of the desired layer, you need to find the highest point and the lowest, measure the difference between them. The laser level is an ideal assistant here. Based on the result, a product is selected. For example, if the required section of the formation is 3 cm, then a thin-layer leveler working up to 2 cm is not suitable. It is cracked, pits and tubercles form due to uneven drying and some other reasons.

Another step is the elimination of visible defects. It is necessary to carefully inspect the floor. Cracks, pits, potholes, bumps and other defects can be duplicated on the upper bulk layer. There are many reasons: poor-quality work, without beacons or level, too much pressure on the needle roller during rolling (it tears out the solution from the recesses), too thin a layer of the mixture, etc. Therefore, in the instructions, manufacturers in black and white indicate:

- To expand, crack, fill and fill cracks, pits and other deepenings with quick-drying repair compounds,

- Knock down protrusions and tubercles, grind with a grinder or sanding mesh for plaster.

That is, the floor needs to be smoothed as much as possible so that after pouring all your efforts do not disappear in vain.

Humidity

Three factors are defined here:

The level of residual water content in the base.

Measurement of base moisture with a moisture meter.

In accordance with SNiP 3.04.01-87 (SP 29.13330.2011), the permissible floor humidity when applying bulk solutions is 2.5-4%. Measurement is carried out by a hydrometer. If the coefficient is increased, then an even floor will not work - excess water will tear off the coating, tubercles, craters, cracks will form.

You can independently approximately determine the moisture content of the base. Carry out peculiar express tests:

- Fix on the floor with adhesive tape polyethylene measuring no more than 1x1 m. Wait a day and check. If condensation, droplets, darkened areas have formed under the film, then the base has not dried out enough. Better to wait a few days and check again. So until the surface remains completely dry.

- Place a basin of hot water on the base and wait. If there is a darkening under it, it is too early to continue work.

Floor absorption.

Perform a quick test: pour some water on the surface. If moisture is absorbed earlier than after 30 seconds, then a primer treatment with waterproofing properties is required. Otherwise, the base will quickly “draw out” water from the solution and the bulk mixture will not gain strength, it will crack.

Indicatorrelative humidity.

Compliance with climate requirements is one of the most important conditions for starting work. According to SNiP 3.04.01-87 (SP 29.13330.2011), flooring should be carried out at a relative humidity of 40-60%. At too high rates, the drying time increases, and at a lower value, the top layer dries quickly, exfoliated, cracked areas appear.

Clean foundation

The technology requires not only sweeping the floor, but vacuuming it, knocking down old paint, removing oil, bitumen stains. That is, remove everything that can impair the adhesion (adhesion) of the bulk floor to the base. If you neglect this requirement, be prepared for the appearance of cracks, swelling, cavities under the coating.

Padding

The soil evens out the degree of surface absorption, improves the adhesion index, and promotes uniform spreading of the solution along the base. It is best to use deep penetration primers or adhesion primers.

If the surface after cleaning is not properly treated or a low-quality product is used, the result may be multiple coating defects, unevenness of the layer, etc.

The following series of problems is associated with a violation of the process:

- The dosage of mixing water is not respected. With an excessive amount, stratification of the composition, the appearance of craters are almost always observed, and with a deficiency, friability and multiple cracks.

- The solution is heterogeneous, poorly mixed. Lumps will immediately be visible on the surface, tubercles and depressions form.

- Not followed recommendations for the thickness of the applied layer. Possible separation of the bulk floor from the base, dips ("bump"), bumps.

- There is no damper tape and expansion joints.

Sticking damping tape.

For rooms with an area of more than 18-36 m 2 (see the mixture instructions for the exact indicator), it is recommended to make shrink sections. Otherwise, multiple deep cracks are provided. The reason for this may be the lack of a damper around the perimeter.

In the remaining 10% of cases, the floor may crack after pouring, the mixture may be to blame due to:

- expired

- violation of storage conditions,

- inappropriate composition (fake or marriage).

In any case, before doing something - consult with specialists. Contact the seller directly, request the contact details of a regional dealer or factory sales representative. Call the hotline numbers listed on the factory sites. Almost no manufacturer ever refuses to consult or consider a claim.

What to do

The elimination of coating deficiencies is possible in two ways: cardinal and local. In the first case, the self-leveling mixture layer is completely dismantled. In the second, damage is repaired.

Exfoliated areas (including those where cavities are felt, “bumping”) are removed, cracks are embroidered, dust-free and abundantly primed. Next, filling with repair compounds or the same mixture that was used previously is carried out. You can additionally reinforce the damaged area with a plaster mesh or fiberglass.

Complete removal of the bulk mixture is necessary if the base has a low grade strength, that is, it is weak. Dismantling also needs to be done when multiple cavities have formed under the new layer, the entire surface has “gone” with deep cracks, swells, swellings,

In some cases, experts recommend another layer device. For example, if the floor is solid, it sits well, but there are minor irregularities. You can use a thin layer leveler or finish mixture.

Advice! If you need repair masters, there is a very convenient service for their selection. Just send in the form below a detailed description of the work that needs to be done, and offers with prices from construction crews and companies will come to your mail. You can see reviews about each of them and photos with examples of work. It is FREE and does not oblige you to anything.

Causes of defects

The main reasons that cause the appearance of damage of various types are associated with a violation of technology in the initial stages:

- incorrectly or poorly mixed composition,

- poorly prepared work surface

- use of poor quality materials.

In most cases, the bulk floor is equipped with a concrete screed. It is important to ensure that it is completely dried. Also, it should not be any pollution. Any dust, dirt or stains of grease will subsequently lead to defects in the operation of the floor.

If you leave the base moist, the release of excess moisture will certainly lead to the fact that areas of the floor will crack or swell.

The screed must be primed. Any irregularities lead to the fact that the polymer composition and the concrete base are poorly bonded, and this leads to the appearance of cracks.

It is necessary to prepare and pour the mixture, observing all the rules and instructions of the manufacturer. The bulk floor will be fragile if you work at the wrong temperature conditions. During the pouring of the floor, the temperature in the room should not exceed 25 degrees.

It is also impossible to carry out work in a cold room with a temperature below 15 degrees.

In rare cases, damage to the bulk floor may occur if it is used improperly. Incorrectly selected detergents and cleaners can damage the integrity of the topcoat, and then it will crack. Excess moisture can also lead to problems with bulk floors.

Most common problems

Frequent problems with bulk floors include cracks. They are shallow, and can even reach the concrete base. Most often, their appearance is due to the fact that the base for the floor was made poorly. If it was fragile, mobile or not sufficiently dried, it will inevitably lead to the appearance of various kinds of cracks during operation.

The bulk floor is also often cracked if the mixture was improperly prepared. The reasons may be the addition of too much water or the use of a solution with an expired shelf life.

In some cases, it is not necessary to completely fill the floor, and you can do without using a self-leveling solution.

It happens that the appearance of cracks in the bulk floor is accompanied by delamination. Another name for this phenomenon is cove. During coiling, a part of the surface on which cracks appear may come off the base. Then she begins to creak and move. Coverage may occur if if a waterproofing layer was not applied to the base or if there are cracks in the concrete screed. Then moisture easily seeps, and the connection between the bulk floor and the base is broken.

The bumpy uneven bulk floor or surface with cavities does not look quite neat at all. In addition, any irregularities will greatly complicate the laying of other coatings on the bulk floor.

These defects are often caused by inaccurate pouring of the mixture or non-observance of proportions during its preparation.

Repair Features

Repair of polymer coatings, as a rule, requires only surface treatment of the top layer or its removal. For more serious defects, it may be necessary to dismantle the coating, or you will have to redo the concrete screed.

It is possible to restore the original shine or eliminate scratches from the surface using polishing. This operation is carried out with a special rotary polishing machine using felt circles. A special composition is applied to them. The restoration of polyurethane floors is performed using protective varnish.

Before any surface treatment, it is very important to thoroughly clean it from dust and dirt, as well as degrease it.

After grinding the surface layer and removing small defects such as bubbles or sagging from it, it is enough to fill the finish layer. Various cracks and delamination require complete removal of the coating from the polymer. Sometimes it’s enough to be limited to a certain area, but it may be necessary to replace the surface layer along the entire perimeter, while the coating is cut to concrete, the concrete screed is ground.

Then they perform the same actions as during the initial installation of the bulk floor:

- degrease the surface of the screed,

- primed her

- apply the necessary layers.

When updating a small area of the floor, it is important to carefully grind all the joints, process them with a special mastic.

Usually, a complete replacement of the bulk floor is done if the damage affects at least 30% of the area. Repair of concrete screed may be required if its poor quality and possible irregularities provoked defects in the bulk floor.

If the concrete is of satisfactory quality, but there are cracks in the screed, substrate restoration necessary. To do this, the cracks are expanded to a sufficient level, then everything is removed from the dust, primed and poured with a repair compound.

Alternatively, injection technology can be used.. First remove the layer from the polymer to completely expose the crack. Then, a hole is made in concrete at an angle, packers are inserted there. Using an injection pump, a waterproofing compound is introduced through the packers until it completely fills the crack.

Cracks or delaminations increase in size rather quickly, therefore do not delay the repair timeso that instead of a separate section, you do not have to re-fill the entire floor.

Crack repair methods

If the floor is cracked, you need to fix the damage as soon as possible. Ways to eliminate them depend on the depth of the crack and its size. With minor damage not exceeding 1 cm in length, there is no need to re-fill the flooring.

It is enough to perform the following actions:

- with the help of tools, the crack is expanded to 2 cm throughout its length,

- remove all dirt with a vacuum cleaner

- on the base and walls, the crack is treated with a primer,

- then the polymer mixture is poured into the cracks, the surface is leveled.

If the area on which the floor cracked is quite large, it is necessary to remove and re-fill the entire area of the flooring with damage. Do this as follows:

- the filler layer is chipped, cleaned and the base is looked,

- if the concrete base contains cracks, use cement putty,

- the site is cleaned from pollution,

- primed on exposed side surfaces, primed the concrete base itself,

- all fill in with a new solution and level.

Tools

To make repair of the bulk coating in the apartment, you need to stock up on a certain set of tools and devices. Recommend to use a respirator. For high-quality mixing of the solution, it is better to use a powerful electric drill, since a poorly mixed composition will subsequently cause defects on the bulk floor.

You can smooth the surface or remove the damaged layer using a grinder.

If coating repair requires a complete refill or topcoat, use a notched trowel. This tool is easier to distribute the substance on a concrete base, and then the tool itself is aligned on the surface.

It is important to choose a tool with a tooth height two times less than the layer thickness. The width of the spatula should not exceed 1 m.

The finish layer is usually applied using a squeegee. This tool is similar to a notched trowel, but it is possible to adjust the width and length of the teeth, so that it is possible to evenly coat the surface with a thin finish layer.

Using a needle roller, you can restore a section of the bulk floor of any area. They evenly distribute the mixture, and remove air bubbles. Depending on the area of the repaired area, a tool of different widths and with different lengths of spikes is chosen.

The building level controls how smooth the floor base and finish are. In this case. it is better to use a device with a length of about 2 m. A primer is applied to the plots from which the damaged material has been previously removed.

It is advisable to choose a long pile.

All tools must be placed in a solvent for at least 4 hours to remove preservation grease. Otherwise, oil may get on the floor, which again leads to the formation of defects.

Additional tools may be needed to restore bulk floors in stock. You should never tighten with repair even minor cracks in the bulk floor, since eliminating them in a timely manner will help prevent more serious problems., which will lead to the need for a complete refilling of the solution.

You will learn about how to repair cracks in a concrete screed in the next video.

Why did the bulk floor crack?

Among all building materials used in the decoration of the floor surface, we can safely highlight the most advanced technology - bulk floor. Cracks and other defects similar in physical parameters are the only minus that can occur when coating is poured. But it is important to note that such costs can occur only in one case - if the technology was violated during the execution of the main process. The reasons for the appearance of cracks in the bulk floor, why the finish layer cracked, what to do if the floor is cracked and whether repairs are needed at all - we will consider these and other issues in this article.

Incorrect preparation of the roughing layer under the self-leveling floor can cause cracks.

Foundation preparation - always a key factor in the quality of the filling process. If during the processing of the base mistakes were made or the prerequisites written in the instructions were ignored, the drying process of the finish layer may be disrupted, which ultimately provokes deformation of the coating and the appearance of cracks. Perhaps this is the main reason that will lead to the need for repair as the design of the house will be spoiled. The screed must be well dried, completely cleaned of dirt, dust, sand and debris.

If a oil or grease stains were found on the surface, they must be completely removed. Then, after complete cleaning, the entire concrete surface must be sanded to a perfectly even horizon. If serious irregularities and differences are observed in the surface, they must first be eliminated. The pouring process cannot be started if the surface has deep depressions and clearly increased humidity. Only after the complete elimination of the listed disadvantages, it is possible to start laying the bulk floor.

Separately worth mentioning on the preparation of a new foundation - concrete screed. After carrying out these works, the finished coating must be given good exposure, at least 20 days, but preferably 23-25 days (this is the period of complete drying of the concrete). If floors are flooded earlier, moisture that is contained in the concrete base can cause the layer to swell, which will invariably lead to cracking. The best evidence of this is not one damaged floor.

Disturbed temperature

If before arrangement of bulk floors there is an extremely low or high temperature, it is not recommended to start the main process. The nominal temperature range is 15–25 degrees Celsius, but not less than 7–8 and not more than 35. You cannot turn on the warm floor if it is in the screed under a dry layer, otherwise the quality in this coating will be poor and its service life will decrease.

Use of household cleaning products

Getting started to clean the finished base, it is necessary to use not only a brush, vacuum cleaner, but also detergents to completely remove old dirt and grease stains. Classical household compositions are better not to use, since such solutions may not completely dry out, as a result of which the floor may subsequently crack and lose strength. To achieve maximum technical compliance, it is best to use acidic compounds (cement scale converter), then grind concrete and remove debris with a vacuum cleaner.

Poor surface priming before pouring

Many incompetent builders neglect priming or use diluted formulations that cannot be done. To completely eliminate cracks, possible dismantling of the bulk floor and laying a new finishing layer, it is better to use the same primer of the same manufacturer in a clean form (without dilution) and apply at least two layers. It is important to remember a simple rule: the subsequent layer must be applied with a roller after the previous one has completely dried. Remember this rule must be used constantly. Uneven priming can lead to disruption of the drying process, which is fraught with the appearance of cracks on the formed surface!

Illiterate base layer fill

Important to rememberthat any non-compliance with the technology or improper mixing of the solution from two-component compositions can result in surface deformation. The pouring process must be carried out in strict accordance with the manufacturer's regulations and the slightest deviation is unacceptable! If you do not have building skills, it is better not to undertake the implementation of this process!

Screed does not match required strength

When is the repair done? screeds or installation of a new base, any inaccuracy can lead to the appearance of defects, which are then proportionally transferred to the finish layer. If you do not want to make a new bulk coating, cracks on the base, and then on the surface should not appear. To exclude repair or re-installation of the self-leveling floor, it is necessary to correctly prepare the base - pour concrete screed.

Repairing the bulk floor - how to remove cracks with your own hands

Having completed the main process, you suddenly found that the polymer layer is cracking, it is necessary to study the “nature and behavior” of the defects, and based on the analysis obtained, make further decisions. Sometimes, for example, if during observation you notice that the crack is no longer expanding, you can not worry - such a deformation is easily eliminated. If there is too much blistering and cracking, repair will not be enough, such a coating may swell again and it is better to remove it. Crack repair is performed as follows:

- For this, the prepared repair mixture is poured directly into the crack.

- This place must be protected before it dries completely.

- After all, the sealed crack is sanded with a fine-grained abrasive sandpaper or paper.

but this method is applicable for simple epoxy, polyurethane coatings or a primer under a multilayer construction.

When many small cracks on the entire surface, repairing polymer floors is impractical. They should be dismantled (together with the base), refill the concrete base and allow it to dry well. Before preparing a new rough floor, you need to familiarize yourself with the recommendations for preparing a concrete screed, read articles, watch a video. To obtain a qualitative result in the future, it is necessary to completely dry the base and only after that start the process of pouring the polymer layer. It is also important to remember about dust removal of the surface and increase adhesion: in order to completely eliminate repeated errors, it is best to double-treat the base with Primer “Polytek”. Following all the recommendations, you can begin to carry out the main process - pouring the finish coating, but at this stage it is important to take into account several mandatory requirements:

- To start pouring, it is necessary to fix the damper tape around the entire perimeter. The thickness of the finish layer should not exceed the parameters recommended by the manufacturer (compliance with this condition will avoid the "cushion effect" and surface peeling during operation).

- To ensure effective drying of the formed coating, it is necessary to create optimal conditions - limited access to fresh air, easy ventilation, but without drafts.

- If polyurethane floors are poured, it is necessary to reverse - create good ventilation, since toxic gas is released during mixing of these two-component compositions.

Separately, it is worth noting that different bulk floors may differ in the conditions for the implementation of pouring, so before starting work, you must carefully read the instructions that came with the mixture purchased.

Professional approach

To carry out installation of bulk floors, you must have basic construction skills. If you are not confident in your abilities, it is better to abandon the independent implementation of these works, since any oversight can lead to cracking of expensive finishing material. The best option is to take advantage of the unique offer of Politek System - the purchase of polymer floors in combination with laying! Having called us by phone you can ask a question: what is better than a laminate, tile or self-leveling floor, how to choose a covering, to mix a solution, how much should be, a way of laying, how quickly we work, and of course about quality.

You can leave your comment, order coverage or cancel the answer through the feedback form. Do not forget to specify your e-mail and name for the answer.

We are ready to offer you device (installation) of the bulk floor in any room. Our materials on a polymer basis can be poured in any room, as they contain additives giving them decorative (for example, colored - tinted according to the RAL color chart, transparent to the picture, linoleum, marble) properties and even other components giving them wear resistance - repair will not be needed for long. For self-application, it is better to see photos and videos on this subject.

Perfect base in order to fill the coating is a material such as concrete (or should be such as a concrete floor or cement screed). The thickness of the coating is variable and very much depends on what basis it will be poured. Calculation can be done by our employees, call our online store and we will tell you the price of materials and the cost of work for your area. Through the form "order calculation" you can ask a question, write a comment - share your opinion and cancel the answer, do not forget, please indicate your name, e-mail, and phone. All products are in stock, there is delivery.

Correct restoration of a bulk floor

Despite the huge number of positive qualities of bulk floors, various defects can occur over time or with poor installation.

But not everyone at the same time has information on how to fix all this, the available recovery methods.

The fact is that in certain situations this can be done on their own, without spending money on attracting specialists in this direction.

Peeling

When such a process occurs, people say that the floors are raised. Swelling can be in a specific place or throughout the area. There are main reasons for this:

- The base for pouring was not prepared well. There was no priming, cleaning from dirt and dust. The adhesion of the mixture to the surface was low.

- Humidity of the basis where the bulk floor is poured. It is necessary to wait for the drying, for example, of the concrete screed completely, and only then carry out the installation.

Many people believe that a large amount of water only helps the finished solution to spread over the area in the room. Some even fill in puddles (drive and primer). As a consequence, this leads to the appearance of defects.

- The surface for pouring has a weak strength.

It is very easy to determine the place of peeling - to tap on the bulk floor with a semi-solid object. A booming sound indicates the need for repairs. If you do not pay attention, then over time, the floor in these places will begin to crack.

Minor damage is removed using a chisel or chipper, after which special repair mortar and grinding are used. It will not be superfluous to run liquid glass at the edges (under a layer of the bulk floor).

With this, the new solution and the old will be well bonded.

There are cases that the floor has such defects in almost the entire room. It will be easier in this version to open the bulk floor to the base and carefully examine it for errors. After performing these activities, the fill is repeated from the very beginning.

Crack removal

Cracks in the bulk floor are the most common defect. It is safe to say that the installation technology was not carried out or did not know about it at all. Minor ones to a millimeter will not play any role, but larger defects should be removed immediately. There will be little work and special experience is not necessary.

The cracks that have appeared must be expanded, cleaned and treated with a reinforcing primer. As soon as the surface dries, special repair concrete is poured into it, and then sanded.

Cracks in the bulk floor can appear periodically, even after they are fixed. This is indicated by the subsidence of the poured solution.

It will not be superfluous to check the base for defects: the floor slab “walks”, the formation of shrinkage cracks in it. In this form, repair will take much more time and money.

Otherwise, it will not be possible to get the perfect bulk floor. Local elimination of cracks on the surface will not give any result.

A large number of cracks cannot be repaired. You should contact specialists who will be able to dismantle the bulk floor and replace the concrete screed, if the reason is in it.

Depreciation and loss of quality

Over time, the bulk floor begins to lose its appearance and original quality. In this case, you don’t need to spend much money, but just fill in a new finish layer, choosing the suitable option for combination with the design.

Among the main reasons for the appearance of such a defect are constant loads. Moreover, such areas may not appear throughout the entire area, but only in certain places.

To get the best quality, it would be better to completely eliminate the old layer of the bulk floor, and instead fill it with a new one.

Before applying new polymers, the old base should be thoroughly cleaned of possible irregularities and defects. This will get the best result. This is how the surface is updated when the interior is changed in the room. The screed layer is negligible and does not affect the distance from the floor to the ceiling in the room.

Cove

Some surface defects of the self-leveling floor can be combined with each other. After being flooded, the floor cracked in certain places. This can still be complemented by exfoliation. This phenomenon is called "cove". In addition to the cracking of the bulk floor, it began to exfoliate, which leads to a creak. There may be several main reasons for this:

- The moisture content of the surface where the bulk floor is poured is more than 4%.

- The surface was not prepared for work (there is dust, dirt). High-quality adhesion is absent.

- No waterproofing layer on the base. Even if it exists, there may be cracks that are transmitted to the finished solution of the bulk floor.

To get rid of such a negative phenomenon, you should remove the area that has moved away from the base, and then thoroughly clean it of possible dust and dirt. Additionally, you can wipe the area with a damp cloth. Then a primer is applied in 2-3 layers. It remains only to fill the self-leveling mixture in one level with the entire surface.

To achieve the best result, an additional layer is poured over the entire such area.

Bubbles and Craters

For such a defect, the following actions precede:

- Poor mixing of the mortar (more often with handwriting or using high revolutions of the drill). All possible bubbles in the process of drying will be displaced in the upper part to the surface. As soon as they are dry, craters and swellings will appear in their place.

- High humidity during work (more than 60%) and the room temperature was below +5 degrees.

- The implementation of the thickness of the bulk floor, which does not meet the minimum parameters from the manufacturer.

- Drops of oil in a solution that did not have time to freeze.

- The mixture is poor-quality used in the work.

Bubbles can easily be avoided by walking with an aeration roller after pouring. It will eliminate them and will not allow subsequent defects to appear on the surface of the bulk floor. But if there are already difficulties, they should be dealt with.

An insignificant amount and size of craters can be eliminated by “instillation” of their solution. When the areas are large, it will be easier and more profitable to fill a new layer of screed. If the bulk floor is cracking, or other defects appear, you should immediately look for ways to get rid of this.

Turbidity

The work is completed, the surface of the bulk floor has dried, but there is turbidity in the form of a whitish hue. This worsens the decorative qualities of the mixture, dullness, weak distinctness appears.

Any pictures or drawings will not look natural. True, while all the characteristics of the operation remain at the same level. The elimination of such a defect occurs on polyurethane or epoxy floors.

The following main reasons are distinguished:

- Drops of fat and other aggressive chemical compounds fell onto the fill.

- The mixture used for work is poorly mixed.

- A large amount of added water.

- The components are not proportioned.

You will have to try very hard to repair the bulk floor with quality. The best option is to make another finish layer. It is very important to pay attention to pouring technology. All proportions and recommendations will be reflected in the instructions.

Chips and potholes

When exposed to sharp or blunt objects with sufficient weight on the surface of the self-leveling floor, not only cracks may appear after pouring the floors, but also chips. The areas together with the polymer composition and the concrete base can break off.

Everything will depend on the degree of impact. The process of surface restoration itself will take a lot of time and effort. It should be cleaned, and then apply a layer of primer and putty if necessary.

At the end, it will remain to fill the layer of the finished solution.

When it is not possible to independently repair bulk floors in an apartment, it is best to contact specialists. They will be able to do everything efficiently and in the shortest possible time.

Saving the floor surface after pouring helps save money. But no one is safe from this and potholes can occur at any time and under any circumstances, when you yourself do not expect this.

Recovery Features

If the bulk floor is cracked, it is necessary to take all comprehensive measures to eliminate this defect. Filling can be performed on top of the old layer, or with a separate area. In any case, you need to clean the surface, in the right places - primer, complete drying before pouring.

Epoxy compositions of the mixture require the use of similar compositions (based on epoxy resins) in the repair of bulk floor cracks.

Studying all the successive steps will be better done on video. All these subtleties will help to find the source why the bulk floor cracked after pouring.

Even in such a situation, before self-repair, you should calculate your strengths and capabilities. When this is nothing, then a direct road to the construction company involved in this area.

Having paid the amount for the service, you will be provided with the truly desired result.

: Culture of repair - bulk floor, grief builders

: Repair of a bulk floor without stopping production lines.

: The bulk floor cracked.

: FLOOR SCREW AND BULK FLOOR. SECRETS OF INSTALLATION AND FILLING.

: Cracks in the screed. Repair screed.

Technology for eliminating cracks in the bulk floor, the reasons for their appearance

There are a huge number of building materials that are used as flooring. And the bulk floor is a confirmation of this. It has high operational and technical parameters that will ensure a long shelf life of the appearance of the coating.

But sometimes it happens that defects appear on the floor. These are cracks, bubbles, holes and other irregularities. We’ll talk about this.

Pits, bumps and bumps

It so happens that on the surface of the liquid floor there are holes, bumps and other irregularities. This indicates poor preparation of the draft foundation. To eliminate troubles, clean the surface, sand and ground in several layers. And fill the pits with a polymer composition identical to the floor covering.

But it is better to prevent the appearance of defects by performing work on pouring the liquid floor in a benign and attentive manner.

Bubbles and swollen areas on the floor

If bubbles and swelling appeared on the surface of the liquid floor, this means that there were irregularities when laying the flooring. For example: after pouring the polymer composition, the surface was not treated with a needle-type roller. The building material was poured on a damp surface or on poorly dried concrete.

To eliminate the coating defect, it is necessary to completely remove the polymer coating. And it will take a lot of effort and financial investment. Cope in a different way will not work. After all, this mistake "little blood" is not eliminated.

Improper preparation work

The main cause of cracking of the bulk floor is the incorrect preparation of the rough foundation. To make a quality flooring, concrete is well cleaned from dust, dirt and debris. The surface should be dry and even.

Only careful preparation of the rough foundation will guarantee a high-quality bulk floor

Greasy and oily traces on the surface, trash are removed. They process a concrete screed so that there are no cracks, holes, bulges and other irregularities. Smooth and smooth flooring will eliminate the appearance of cracks on the bulk floor.

Important! Pour the bulk floor onto a concrete screed, which is well dried. This is not earlier than twenty days after completing the screed. Otherwise, residual moisture will cause cracking after pouring.

Deviations from the recommended temperature

Performance of work requires compliance with the recommended temperature conditions in the room. Too high and low temperatures are dangerous. And if it happened, then it is impossible to avoid a crack in the bulk floor.

To prevent such a mistake, it is worthwhile to fill the liquid floor exclusively at a temperature of 15-25 degrees Celsius above zero.

Use of inappropriate detergents

When preparing a concrete screed, in addition to a rag soaked in water and a vacuum cleaner, detergents are needed. But apply what is in the kitchen is not worth it. It is important to take specialized compounds. After all, the usual washing liquids are poorly washed off. And this in the future can lead to cracking of the bulk floor.

It is forbidden to clean the concrete base with ordinary detergents. This will cause cracks in the floor.

To obtain the desired result, use acid - a specialized cleaner of cement deposits. To grind the surface is a grinding wheel. This is the only way to achieve the desired smoothness and evenness.

If the surface is poorly primed

There are situations when, due to the economy of the primer or ignorance, poor-quality priming of the concrete surface is obtained. As a result, uneven adhesion of the floor surface: in different areas, the liquid self-leveling composition does not adhere equally to the base.

Primer coating

The technological process of creating a liquid floor involves applying at least three layers of a primer mixture. And the application of each subsequent layer is made after the previous one dries.

Important! If you independently carry out work on arranging a liquid floor and avoid cracking or covering with other defects when it dries, you should carefully study the instructions for using the primer. The manufacturer always describes how to use the composition. If done according to the instructions, you can avoid problems.

Poor polymer fill

In case of trouble, everything can be repaired. But it is better to prevent the formation of defects. Do not pour the polymer compound on uneven, dirty and rough concrete. Stick to repair technology.

Filling the floor with a liquid polymer composition

When mixing the mortar, when pouring the concrete screed, follow the manufacturer's recommendations. This concerns the homogeneity of the liquid composition. There should be no lumps in it, since the base will be damaged.

Important! What to do and how - in the instructions for the use of building materials. Depending on the composition, the methods of kneading the solution are different.

Insufficient flooring strength

If the screed is not strong enough and reliable, it will break during operation and lose its attractive appearance.

When a screed needs leveling and hardening

As a result, you will need to spend money on repairs. And the rough foundation will have to be repaired again. Only a clear and high-quality implementation of construction procedures at each stage guarantees the result.

Technology for eliminating flaws in the liquid floor

If any defects appear on the bulk floor, seek qualified help. But if there is no money for this, you can cope with the task yourself. For this, epoxy resin is useful for repairing cracks or much more.

Epoxy for repairing cracks on the surface of the bulk floor

How to remove cracks in the floor?

- If the crack is up to a centimeter, at least double.

- Then dust, dirt and debris are removed in the resulting gap. It is important to achieve cleanliness. To do this, use a vacuum cleaner that quickly and efficiently cope with the task.

- The crack cavity is treated with a primer. Epoxy is used to fill the gap. Although there are many specialized tools.

Filling a gap in a polymer liquid floor

- The composition fills the gap cavity, is accurately leveled.

Important! You can talk about the quality of the work done after 30 days.

Only after this time the composition will completely dry.

How to replace problem areas of bulk flooring?

- When areas that move appear on the bulk floor, they are removed. To do this, the screed is removed to a strong and strong flooring.

- After removing the damaged surface, inspect the concrete screed. Most likely there is a crack in the concrete in this place, so a defect has appeared.

- When the black base in this place is also movable, also remove until it lags behind. Otherwise, the swelling will recur.

- The surface to be repaired is cleaned with a vacuum cleaner and opened with a primer for good adhesion of the coating.

- After the primer composition has dried (about a day), they begin to seal the hole with a standard polymer material, which was used to equip the liquid floor.

Conclusion

The main reason for the appearance of defects on the floor liquid flooring is poor-quality flooring, non-compliance with the technological process. It is better to use the services of professionals. But if this is not possible, you can do it all yourself. But follow the instructions. To do this, it is recommended to watch the following video:

Average rating of ratings over 0

The destruction of the polymer layer

In practice, there are usually 6 types of problems localized in the polymer itself:

- Abrasive wear.Natural abrasion of the surface occurs after prolonged use. Accelerated wear can be observed with the wrong choice of floor material that does not correspond to the level of loads at the facility. Wear is accelerated also in the absence of a protective varnish layer.

- Turbidity, stratification. It can be observed due to excessive total thickness of the layers, violation of the installation technology, use of low-quality materials.

- The formation of bubbles.It is associated with porosity of the base and insufficient air removal by a needle roller.

- The formation of tuberosity and sag.It occurs due to the increased viscosity of the mixture, as well as due to installation at excessively high temperatures, accelerating the curing of polymers.

- Emission of uncured resin.It is expressed by stickiness of the surface and accelerated dusting. The reasons are the use of substandard materials, imbalance when mixing the resin and hardener, as well as insufficient mixing. It is also possible that increased humidity during installation interrupted the curing process.

Substrate Issues

Poor quality concrete screed, violation of the installation technology of bulk polymer floors, as well as the unintended exposure to moisture lead to the following consequences:

- The formation of blisters, cracks and delamination of the polymer layer. If the self-leveling floor is peeling off the primer, this is due to contamination, dusting or moisture that have fallen on the substrate before pouring the polymer. If the primer exfoliates with the polymer, the reason is poor quality concreteor in violation of installation technology. This may be failure to polish concrete, insufficient dedusting and degreasing, priming on a damp surface.

- Cracks without loss of adhesion to the substrate. The polymer exfoliates along with a primer and a layer of concrete. The reason is the poor quality of the substrate.

- Craters and through pores.If the thickness of the polymer layer is sufficient for guaranteed closure of the pores of the base, then the reason for the formation of craters lies in the absence of a primer layer.

Defect analysis

In cases where the nature of the damage does not indicate a low quality of the substrate, it is sufficient to determine the boundaries of the proposed repair using a trial removal of the coating. In several places, it is necessary to measure the humidity of the concrete screed to determine the full terms of reference for the upcoming work.

When analyzing the causes of peeling of the polymer layer, not only a moisture meter should be used, but also a hardness meter, as well as a building thermal imager. Only this device guarantees the detection of hidden sources of moisture in concrete.

Cosmetic restoration

To remove visible scratches to the eye and restore the original gloss of the epoxy coating, you can use polishing. The operation is carried out by a rotary polishing machine with felt circles, on which a special emulsion is applied.

Restoration of polyurethane floors is carried out by applying a protective varnish.

Any surface treatment is preceded by thorough cleaning, dust removal and degreasing.

Repair with the removal of the polymer layer

In some cases, it is enough to remove only the top layer of polymer by grinding with diamond wheels. This is done when renovation is subject to coating with influxes, bubbles, surface discoloration.

A new finishing layer is poured onto the polished surface. If the area of fixed defects is small, you can do without an industrial rotary installation.

For local grinding, a conventional manual angle grinder is used.

Repair of cracks and delamination involves the complete removal of the polymer coating. In the case when the quality of the concrete substrate is not satisfactory, but they are going to remove the old fill over the entire area of the room, the sequence of actions looks like this:

- Where the coating has poor adhesion, scraper nozzles for a perforator are used for removal.

- In areas with preserved grip, bit-type nozzles and grinders are used.

- The exposed surface of the concrete screed is polished.

- A sequence of actions corresponding to the installation technology of the polymer floor is carried out: dust removal, degreasing, priming, applying the first layer, etc.

If the coating is removed in a limited area, the perimeter of the repair work is first determined (it is made in the shape of a rectangle). Then the coating is cut to concrete along this perimeter. Further work is carried out, as with the complete removal of the floor. The only difference is that the joints with the old coating are sanded and processed with special mastic.

What are the selection criteria: completely remove the coating or carry out local repairs?

If decorative properties are important (for example, in offices and shopping centers), then local repair is appropriate even with a satisfactory general condition of the surface. The decision to completely replace the polymer floor (regardless of the type of facility) is taken, as a rule, if more than 30% of the bulk coating area is damaged.

When replacing the coating locally, materials of the same type that have already been used should be used. An exception is cosmetic repairs using methyl methacrylate mixtures. They work well in contact with other materials. The advantages of methyl methacrylates are the speed of the work, the disadvantages are the low abrasion resistance.

Concrete base repair

If the peeling of the polymer layers occurs due to the poor quality of the concrete substrate and the unsatisfactory state of waterproofing, then you can not do without screed alteration.

If cracks in the screed are found with satisfactory quality of concrete, the substrate should be repaired. The traditional restoration technology consists in cracking the cracks to the required depth, followed by dedusting, priming and filling with a polymer repair compound.

Recently, an alternative technology called injection has begun to develop. First, the polymer layer is removed to completely expose the crack.

Then, at an angle of 45 °, holes are drilled in the concrete in the direction of the crack along its entire length in increments of 30–40 cm. Special fittings — packers — are hermetically inserted into the holes.

An injection pump is connected to the packers and a waterproofing composition is introduced before it leaves the crack.

All repair operations after sealing cracks are similar to those described in the previous subsection.

Summary

Do not delay when starting repairs. The price of delay is that instead of cosmetic or local renovation you will have to completely change the polymer coating.

Defects such as delamination or cracks tend to increase rapidly in size. But especially hurry should be in case of emergency chemical destruction of polymers. To prevent the reaction from continuing in the thickness of the material, it is necessary to limit the lesion site and completely remove the polymer layer from it.

In what cases does it make sense to save on the call of specialists and do-it-yourself repairs? The decision to renovate independently is economically justified when the proposed work is limited in size and does not require the rental of expensive equipment.

For example, having carefully studied the technology for working with repair compounds and armed with a cutter, punch, scrapers and a conventional spatula, you can replace the coating in small areas.

But this makes sense only if the necessary materials are available for sale exactly in the quantity in which you need them.

Defects of the bulk floor: causes and remedies

What could be simpler than bulk floor technology? We mix the components, pour the mixture onto the floor and get a perfectly aligned surface.

This is what most home masters think, who decide to independently carry out the procedure for creating a bulk floor. However, this simplicity and ease of technology is only apparent. According to some reports, only 30-40% of all bulk floors are ideal.

Others have defects associated primarily with violations of the technology of their device.

Many damage to the bulk floor can be repaired without major repairs, that is, without completely dismantling the surface. Typically, the identified marriage is blocked by an additional finishing layer of a self-leveling mixture. But there are also more complex defects, for the complete elimination of which it is necessary to open the floor, completely remove the bulk layer and even repair the concrete base.

Common defects:

- peeling, swelling of the finish layer,

- surface cracks

- cove

- small inclusions, foreign particles on the surface,

- delamination, clouding,

- mounds and depressions,

- premature wear.

If these signs of destruction occur, it is time to begin repairing the filler surface. Consider the restoration methods that must be carried out with one form or another of deformations.

Defect number 1. Bloating, peeling of the filler surface

Swelling is manifested as the formation of single or multiple bubbles on the bulk floor. Their surface can become covered with cracks (if the layer is thin) and collapse. In this case, we can talk about exfoliation.

The cause of swelling and exfoliation is insufficient adhesion (adhesion) of the bulk layer and base. The coating, not properly glued to the base, begins to move away from it.

Errors in technology leading to bloating and exfoliation:

- Inadequate cleaning of the concrete base from dust, grease stains and other contaminants.

- The use of low-quality primer.

- Laying the filler layer on a damp base. In this case, excess water and condensate rejects the bulk layer, bubbles and exfoliation form.

- Low grade strength of the concrete base.

- Failure to comply with the time interval between application of the layers of the bulk floor.

- Coating components are not thoroughly mixed before pouring. Mixing should be performed only mechanically, using special nozzles.

- Unfair removal of air bubbles from the coating using a needle roller. Bubbles remaining in the thickness of the coating, during drying, move to the surface and leave behind them swollen bubbles or bursting "craters".

- Violation of temperature and humidity indicators in the room. According to the technology, during work, the room temperature should be above 5 ° C, and humidity should be below 60%.

Elimination of blisters and peeling:

- All swellings must be removed. You can clean bubbles and formed “craters” with a grinder or manually - using a spatula.

- They clean the floor of small particles of construction debris and dust. To do this, vacuum the surface, do wet cleaning. Before proceeding to the next step, the substrate is thoroughly dried.

- Primed places of defects, if necessary - twice.

- Fill defects with the used self-leveling mixture. Alternatively, polymer or cement putty can be used. Cement putty is intended for cement bulk floors, polymer putty is universal, many of them can be used not only for polymer, but also for cement (or concrete) coatings.

If the poured floor is not front, then at this step the repair can be completed. The bulk floor, used as a front coating, needs a complete visual masking of the “patches”. Therefore, the entire floor is poured with a finishing bulk layer, fully adhering to the manufacturer's instructions for the self-leveling mixture.

Defect number 2. Cracks

Cracks - a frequent defect in the bulk floor. Sometimes they are shallow, sometimes they reach the concrete base. Usually, the appearance of cracks is associated with a poor-quality base on which the bulk floor was laid. This is the most common cause, but not the only one. Also, there is a violation in pouring technology.

Causes of cracks:

- Too thick filling layer (more than 7 mm).

- The presence of cracks on the base.

- Loose base, prone to movement.

- Insufficient base reinforcement.

- Non-observance of the proportions of the components of the bulk mixture, namely the addition of more water than required by the instruction. Too liquid solution often cracks when dried.

- Application of the bulk mixture on a wet screed.

- Use of an expired bulk floor mixture.

If the cracks are single and the bulk floor is not a front coating, it is not necessary to completely re-fill the floor. The optimal solution is to fill such cracks with a self-leveling mixture.

The process of filling cracks:

- With a small crack width (up to 1 cm), it is expanded to about 2 cm along the entire length. This can be done with a grinder (grinder) or a metal brush.

- Remove dirt from the walls of the crack, pull the dust with a vacuum cleaner.

- The walls of the crack are treated with a primer and allowed to dry. If necessary, repeat the treatment.

- The crack is filled with polymer or cement putty, leveled flush with the rest of the surface. If necessary, fill the entire floor with a new bulk layer.

In the event that the floor is cut with a network of cracks, filling them no longer makes sense. It is necessary to completely dismantle the coating and evaluate the condition of the concrete base - most likely it was it that gave impetus to such deformations. If errors are found, first repair the base, and then fill the self-leveling mixture again.

Base repair usually consists in filling all cracks existing in concrete (screed) with cement mortar or putty. The surface should be level-aligned, the allowable differences between the highest and lowest points - no more than 2-3 mm.

Defect number 4. Hillocks and hollows

Sometimes the bulk floor is uneven. After drying, hollows (pits) or tubercles are clearly manifested on it. Such a defect not only reduces the decorativeness of the floor, but can also prevent the laying of the finish coating (laminate, parquet, etc.) on it.

The causes of the appearance of hillocks and depressions:

- Uneven concrete base.If there are significant bumps or depressions on the base, then all these defects are more likely to be printed on the surface of the bulk floor.

- Filling the mixture "by eye".

- Failure to comply with the recommended proportions when mixing the components of the bulk mixture. If during the mixing process more water was added than the instruction requires, then, after drying, depressions often appear on the surface. If, on the contrary, little water has been added, the surface becomes hilly.

To remove the tubercle, the floor is ground. Then fill the surface with a finish layer of a self-leveling mixture.

The cavities are filled with putty (on an epoxy or cement base) or with the same self-leveling mixture, which is used for the entire coating. After drying, put the final bulk coating (if necessary, if the bulk layer is front).

Defect number 5. Small inclusions, roughness

If dust or small particles of debris get on a dry bulk floor, then pimples, roughness, small irregularities form on its surface. In this case, it is impossible to achieve a mirror, absolutely smooth surface.

- Insufficiently cleaned concrete base, the dirt from which fell into the bulk mixture and spread over its surface.

- Dust floating in the air and deposited on an as yet uncoated bulk surface.

Elimination of small roughness:

- The surface of the floor is cleaned from dust.

- Apply a thin topcoat overlying defects.

Defect number 7. Premature wear

The service life of the bulk floor is up to 10-20 years (polymer coatings are more durable than cement ones). Therefore, if after a couple of years of operation, the floor began to crumble, turn white (from scratches), then we can talk about its premature wear.

Causes of premature wear:

- Reinforced load on the surface (in workshops or in warehouses where transport is moving or heavy mechanisms are installed).

- The use of expired components of the bulk mixture.

To update a coating that has become unpresentable, simply apply another thin top coat on top of the existing layer. Particular attention should be paid to the selection of high-quality components of the mixture and compliance with the technology of pouring the bulk floor.

If there are noticeable chips on the surface, then they are primed and filled with putty (on a cement or polymer basis). After that, fill the floor with a new bulk layer.

Thus, almost any defects and deformations of the bulk floor can be corrected. However, it is best to be proactive, avoiding technological errors during the creation of the bulk coating.

Use of the wrong detergents

During the cleaning of the concrete base from dust, dirt and other contaminants, they should be cleaned not only with a rag of a vacuum cleaner and a brush, but also use detergents.

It is forbidden to use detergents intended for ordinary household needs. Because such cleaners are not completely removed during cleaning, and this may cause the final coating to crack.

For proper cleaning of the concrete base, it is necessary to use specialized acid (cement scale converter). And then you need to grind using a grinding wheel and a grinding machine.

Poor surface primer

The primer of the base should not be neglected, because if the surface is treated unevenly, then the final coating in the form of a self-leveling floor will dry out unevenly, which means that the surface will crack, cracks will form. Therefore, it is better to make priming several times so that later you do not have to redo the bulk floor.

A new coat of primer is applied only after the previous one has completely dried out. The time required for this is indicated on the packaging of the primer.

Weak screed strength

In the case of poor-quality rough screed, the self-leveling floor will collapse after deformation of the base. Therefore, in order not to make repeated repairs of the bulk floor, which will result in additional financial costs, you need to properly fill in a new rough screed or fix defects in the old coating.

Repair of cracks in the bulk floor

First you need to determine the nature of the appearance of the defect and trace its behavior, and then decide what to do if the floor is cracked.

If after some time the crack has not increased and new flaws have not formed, then such a defect is easily eliminated. The closure of such a crack is as follows:

- The prepared mortar for poured floor is poured into the crack.

- The place of damage with the filled solution is left until it completely dries.

- Then grinding of this place is carried out using fine-grained emery paper.

Such a repair method is only suitable if the self-leveling floor is the basis for the subsequent final coating, for example, for porcelain tiles.

If cracks appeared in several places, and they also have many small branches, then it is not advisable to carry out restoration work. In this case, unfortunately, it will be necessary to remove not only the bulk floor, but also the rough screed up to the tiled floors.

After thorough cleaning of the surface, you should start pouring a new screed with strict adherence to the entire process. After pouring the screed, wait until the screed has completely and naturally dried.

After drying, the surface must be primed. This stage is performed twice, since a high-quality primer will ensure reliable adhesion of the base and the self-leveling floor, which will avoid the formation of defects.

Then go directly to the filling of new bulk floors. At this stage, you need to pay attention to the following nuances:

- A damper film must be fixed on the walls.

- The size of the poured floor should not exceed the thickness specified by the manufacturer. Otherwise, the flooded floor will acquire the so-called cushion effect, and this, in turn, will lead to delamination of the coating in the future.

- During the filling of the floor, drafts and the access of fresh air are not permissible.

An exception in the form of a ventilation assumption is the pouring of a polyurethane bulk floor. Since during its installation toxic gas is released.

In this material, the main causes of the appearance of cracks in the bulk floor and methods for their elimination were considered. So that you are not interested in overgrowing “bulk floor crack repair”, you must strictly follow the technology and responsibly approach the preparation of the foundation, then these troubles can be avoided.