In fact, this material differs from the typical only in form. And by the way, many choose the laminate with squares, since it is very similar to tile, but at the same time it imitates wood (according to the surface texture). Like any other building material, it has its advantages and disadvantages. So, the pros include:

- Easy to clean and resistant to various cleaning agents.

- Does not absorb all kinds of contaminants (dust, dirt, grease stains).

- Equipped with antistatic surface.

- It is characterized by abrasion resistance, that is, it does not wear out over time.

- It is simply mounted and dismantled.

- It has high thermal and fire resistance.

- A wide range of colors allows you to use it in any interior.

Of the minuses, one can distinguish relative vulnerability to moisture and the synthetics of the materials used. How is it that, it would seem, the top layer should perfectly protect from water ... In fact, the way it is, the joints of the laminate boards are vulnerable. That is why, due to flooding, the coating may begin to flake.

Laying a square laminate

The difference between installing a square laminate from a typical installation is only that it does not require a substrate. It can be laid directly on a concrete screed or any other coating (solid board, linoleum). However, the rest of the process is absolutely identical. First, the material is removed from the packaging for several days. He must "get used" to the existing humidity and temperature. Then proceed to the installation itself, carefully laying out the first row.

The direction of the masonry should be "on yourself". The connection method is lock Click or Lock. The first involves a collapsible mount, the second - a latch method. “Click” is considered the best, since then it can also be easily dismantled in the same way. After you have laid the first row, proceed to the second and third.

In the process of flooring, it is important to observe the symmetry of the pattern and to ensure that there are gaps - 2 mm per square meter.

Plus, it is important to leave gaps near stairs, pipes, walls, thresholds. Between the last row and the wall, as much as 10 mm is left. This is necessary because the coating itself can both taper and expand over time. At the finish stage, skirting boards are fixed, which must match the texture and color of the coating.

Advantages and disadvantages of a square laminate

The advantages of this material are similar to the classic version. Characteristics largely depend on the quality of the laminate flooring, the manufacturer, the selected class.

The following advantages are distinguished:

- strength,

- moisture resistance

- antistaticity

- Fire safety,

- easy laminate care and installation,

- low cost per square meter, a wide range of textures and colors,

- advanced opportunities for creating unique designs by combining styling methods, shades, textures.

There are also disadvantages:

- Imitation of natural materials. In production, waste from the woodworking industry using glue is used. It is on its composition that health safety depends.

- Inability to repair. If the panels are significantly damaged, they cannot be looped, sanded and varnished like natural fibers. Such cloths must be replaced.

A large number of advantages have made laminated floor panels the leaders in the finishing range.

Square laminate

Square laminate

Structure and grades of square laminate

This finishing material has a multilayer design, consisting of four or more layers:

- Lower stabilizing layer. Protects from moisture penetrating from the base and prevents deformation of the paintings.

- Particleboard or fiberboard. Bearing layer. The castle connection is located on it. The quality of the service life of the flooring depends on the quality of the lock.

- Decorative. It is made either from polymeric materials, or from paper on which drawing and color are applied.

- Protective face layer. Its quality and thickness is responsible for the safety of panels from moisture and mechanical stress.

An important factor responsible for the durability of the flooring and its strength is class. Two-digit numbers are used for designation. The first figure is responsible for the category of the room where the coating will be laid: 2 (household), 3 (public). The second figure gives an understanding of resistance to mechanical stress: 1 (weak), 2 (medium), 3 (high), 4 (very high). The minimum value for the laminate is 22, the maximum is 33.

Lay square laminate

Lay square laminate

Another important safety classification for health. Put the laminate with the marking E0 - to ensure the most healthy microclimate in the room. The use of such material is recommended even for health and children's institutions. E1 - contains the minimum amount of toxic substances (formaldehyde), and E2 and E3, the harmfulness is within the normal range, but this coating should be used with caution.

How to choose a good laminate?

In the context of one apartment, canvases of different strength classes may be needed:

Having decided on the classes, laminate squares should be considered for other characteristics:

- Manufacturer. It is better to choose coatings of famous brands. This will serve as a guarantor of quality.

- Certification This document will confirm or refute the product safety voiced by the seller.

- Type of castle connection. LOCK and Click. These are the two most common types. The first is distinguished by a low price, the second - by the quality of the received connections, the service life and the possibility of dismantling / installation without breaking the paintings.

- The presence of additional wax protection of the castle. Provides a tight fit and water repellent properties.

- Visual inspection Panels should not be deformed, have bubbles and chips.

- Repeatability of the picture. If you mean imitation of parquet or solid, then the less the repetition of the pattern occurs, the more natural the floor will look.

- Additional characteristics. Sometimes heat and sound insulation are important. A material with the required protective layers should be selected.

- Sizes. Attention is paid to the thickness of the panels. The optimum will be 7-8 mm. Provides a normal level of strength, thermal insulation.

Choosing the right flooring is half the success, laying a laminate with your own hands in a quality manner is the second crucial part.

Rules for laying laminate flooring

Installation of flooring is not difficult and there are several common points:

- Foundation preparation. Some manufacturers voice a margin of error of up to 2 mm. With an even base, the flooring will last much longer.

- Waterproofing. Laying a square laminate directly onto the screed is not recommended. Since cement has increased hygroscopicity, excess moisture will be transferred to the canvas, which will lead to deformation and rapid wear.

- Technical clearance. Be sure to leave 10 mm around the entire perimeter. The gap along the walls is fixed with special pegs at a loss. If a thresholdless connection is planned, then the manufacturer's recommendations on the allowable area should be taken into account.

- Wax protection. It is better to provide for such processing locks. Additional protection will ensure a tight fit of the paintings, water-repellent properties.

Before installation, the material is unpacked and allowed to lie down for up to 2-3 days. During this time, the canvas incorporates the features of the microclimate (humidity, temperature). This will minimize shrinkage after installation.

DIY square laminate flooring

DIY square laminate flooring

If the system is planned underfloor heating, then the distance between the laminate and heating is recommended at least 30 mm. And the temperature should not exceed 27˚C. When choosing a material, pay attention to whether there is a tolerance for using a warm floor under the system. These are the general rules for laying flooring, characteristic of a parquet board, parquet, laminate.

Useful video: Laying the art square laminate

Installing a Square Laminate - Walkthrough

I distinguish three stages of work:

- Preparatory stage:

Laminate flooring requires a flat surface. Therefore, we consider two options for preparing the foundation:

- Concrete. It should be without cracks, grooves, height differences. If necessary, pour self-leveling one-component self-leveling floors. This will provide the most even surface.

- Wood floors. Squeaky cloths are replaced. Plywood flooring is recommended. In the case of a critically uneven base, a wooden leveling frame is made with a cell pitch of 300-600 mm. Cover with plywood 20 mm thick.

The subtleties of installing a square laminate are the ability to combine color and size. But the material is carefully selected, because the thickness of the panels and lock joints may vary. Features of installation consist in observing an even cross connection of the canvases. Laying is carried out in rows. First, one row is assembled, fixed from the walls by wedges. The second is going, connected to the previous one. Depending on the lock, installation is carried out with padding or simple snap-on.

How to lay a square laminate

How to lay a square laminate

- Stacking procedure

I single out two main ones:

- Classic. Recommended for small rooms. Installation begins from the far corner of the room.

- Diagonally. Recommended for large rooms. If you decide to independently install the flooring, then you should know that work begins from the door. Panels are placed under 45˚.

Installation of laminated flooring at home is quite feasible on our own. Important is the selection of material, compliance with the technology of work, manufacturer's recommendations. A square laminate expands the possibilities for designers to create unique interiors. And ease of maintenance and installation, low cost - the key to growing popularity.

What is a laminate flooring?

Look at the bar layout:

1 - transparent wear-resistant layer for protection,

2 - a decorative layer, reproduces the pattern of natural wood, stone or ceramic tiles,

3 - the basis of a high density fiberboard (HDF) is responsible for the stability of the strip, stability,

4 - stabilizing layer, prevents deformation of the strap.

Where can I stack

This is truly universal material. It can be laid in bedrooms, living rooms, nurseries, hallways and kitchens.

They also began to actively lay in country houses, including seasonal residence. But this is risky, since the guarantee applies only to decoration in residential premises with a constant temperature and slight fluctuations in humidity: from 30% in winter to 60% in summer.

A seasonal country house does not heat up most of the cold season, and, of course, the floors in it either heat up or cool down. Such climatic disasters are not useful for decoration.

Today, the material can also serve as the original decoration of the walls. The planks are fixed directly on the base with silicone glue and studs (nails without a hat) or on a wooden crate. Of course, you should not use such a cladding near water sources, as a kitchen apron or wall decoration in the bathroom.

Heavy objects do not attach only to the wall decoration. Their reliable installation will be ensured by fasteners passing through the laminate and fixed in the bearing part of the wall.

1. Wrong choice of wear resistance class

The most common mistake is the wrong choice of wear resistance class. The parameter affects the price, so many in an effort to save money take the cheapest option, forgetting that it is not suitable for rooms with high traffic. A typical case: the happy owners of a new building took a beautiful, but cheap product and bed it all over the apartment, including the entrance hall. And after a couple of rainy seasons, it deteriorated from constant increased humidity and mechanical stress.

Therefore, the first thing you need to pay attention to is the class. It shows how durable the coating is, abrasion and scratch resistant. In specialized stores and chain hypermarkets, the entire range of decors from bleached to dark is usually presented in different classes. Therefore, you can find a suitable item in color and texture.

Before going to the store, first of all, determine for which room you select the flooring, the choice will depend on this. For example, for rooms with low traffic, such as bedrooms or living rooms, 31 class is suitable, and for rooms with medium traffic - kitchen, living room, nursery, corridor or office - it is better to use a more durable 32 class. For rooms that have the highest load, it is better to choose products of class 33, they can even be laid in the hallways.

For your convenience, we have compiled a summary table. It notes for which rooms which class of laminate is better to choose.

Bedroom, living room (for a small family), study

Children's, living room for a large and welcoming family. Kitchen or hallway

Great for an apartment with pets

Bathroom, kitchen or hallway

2. Wrong thickness

The second important parameter that determines the quality and performance is the thickness of the board. It affects how noisy the flooring will be, that is, the thinner the better the neighbors will hear your steps.

The thickness of the cheapest product starts from 6 mm, and the thickness of the boards of the expensive 33 class coating can reach 12 mm, like a parquet board. This often comes across lovers of money, who choose a product level higher, but do not take into account the thickness, as a result, get a scratch-resistant, but very "noisy" floor.

What thickness of the laminate to choose for the apartment? If heavy furniture and equipment are installed in the room, it is better not to use a coating thinner than 10 mm, otherwise it will not withstand long static loads. However, if you plan to lay the slats on a warm floor, choose thinner boards, as they will better allow heat to pass through.

3. Inappropriate shade

To make the room look harmonious and visually “not fall apart” into separate parts, all finishing materials must be designed in the same color scheme - warm or cold, even if they are in contrasting shades, such as a dark floor and light doors.

If you want to visually expand a small room, use light cold tones in the decoration, and if you want to make too large a space more comfortable, choose a warm color scheme.

When choosing, we advise you not to rely only on memory, but be sure to take samples of the materials that you plan to use in the interior, and watch how they fit before you buy.

4. Moisture resistant laminate mixed up with waterproof

Humidity is one of the main enemies of this material: if water gets into the joint, its boards easily absorb and swell, irregularities appear from this and the decorative coating departs. Manufacturers have taken this feature into account and offer waterproof options that can be stacked in rooms such as a kitchen and even a bathroom. If you decide on such an experiment, the main thing is not to mix up the waterproof and waterproof laminate.

What is the difference? The moisture-resistant board is based on a high-strength fiberboard, it is treated with paraffin and other compounds that can protect the board from moisture only for a while. This coating will withstand various contaminants and wet cleaning, prevent the development of mold and fungus. But if you do not immediately wipe the water from the surface, it will penetrate into the joint, the finish will begin to deform and rise, as a result, the floor will become uneven. Moisture-resistant laminate changes its volume during temperature changes, therefore it is suitable only for kitchens and hallways. But for the bathroom, sauna, balcony or porch, it is no longer suitable.

Only a waterproof type can survive direct contact with water. It is able to withstand prolonged exposure to water, does not deform when temperature changes, and practically does not wear out. All joints of a waterproof floor are treated with heated wax, and the surface is not slippery and gives it antistatic properties so that dust does not settle on it.

5. Thoughtless savings on the substrate

Another typical situation when, when preparing estimates for repairs, they forget to turn on the substrate. As a result, you have to spend time on additional trips to the store. Or they take the cheapest version of the substrate if the entire budget has been spent, and then they regret it very much. After all, a high-quality substrate not only levels the concrete surface, but also provides additional noise and heat insulation, softens the shock load and extends the life of the floor covering up to 5 years.

A cheap substrate has a big but unobvious minus - the smell. Of course, the unpleasant odor will disappear, but from this the substrate will not stop releasing chemicals that can be toxic and cause allergies. Therefore, we recommend that you do not save and choose options from natural materials, for example, cork or coniferous substrate.

The technical plug is not electrified, which means it does not attract dust, does not absorb odors, is hypoallergenic and contributes to the natural regulation of the indoor climate in the room. Coniferous substrate is made of 100% natural materials - coniferous wood. It significantly reduces "shock" noise, the room will become significantly warmer due to the low thermal conductivity of the material. The density of the coniferous substrate is selected in such a way as to smooth out small irregularities of the “rough” floor and protect the locks from excessive pressure.

The final elements include skirting boards of various heights, widths, configurations, as well as lining on the inlet openings of the elements of the heating system and sills.

Laminate for an apartment: distinctive features

For living rooms, a laminate is often the best solution. In addition, choosing a laminate for an apartment is very simple. A high-quality laminate practically does not differ from a natural tree either in appearance or in touch, it is available in various patterns, textures and in different shades. At the same time, this flooring is environmentally friendly, safe for both people and animals, does not have an unpleasant "chemical" smell and does not emit harmful substances.

Caring for the coating is very simple, it is not afraid of humidity, it is easy to wash. This is especially important for families with young children and pet owners - unlike carpeting or parquet, laminate flooring is very easy to keep clean.

According to the quality of the external coating, the laminate is divided into several classes, indicating primarily its wear resistance. Today in the market you can find laminate flooring 31, 32, 33 and 34 classes. 31 and 32 are suitable for almost any room in the living area. 33 and 34 classes are used in places with increased traffic - shopping centers, cinemas, hospitals, hotels, bars and cafes - that is, where the flooring is constantly experiencing heavy loads.

What class of laminate flooring is best to choose? It depends on where and how you are going to use it. In rooms where there are constantly people, it is better to put a laminate with a class above, and for bedrooms, pantries and walk-in closets, a laminate of class 31 is quite enough. With proper care, a laminate of class 31 in an ordinary apartment can last up to 12 years, 32 to 15, 33 to 20, and the most durable laminate of class 34 does not require replacement for 25 years.

To choose the right laminate, you need to take into account the nuances regarding its thickness. It can be 5, 8, 10 or 12 millimeters. On the one hand, the thicker the laminate, the stronger it is. A thicker laminate is preferable for rooms where the quality of the base coat leaves much to be desired. However, it is much more profitable to provide a quality base coat and use a thinner laminate. In addition, it is important to consider that in the presence of underfloor heating, a laminate of a smaller thickness instantly heats up: this means that you do not have to wait and increase the heating power.

Features

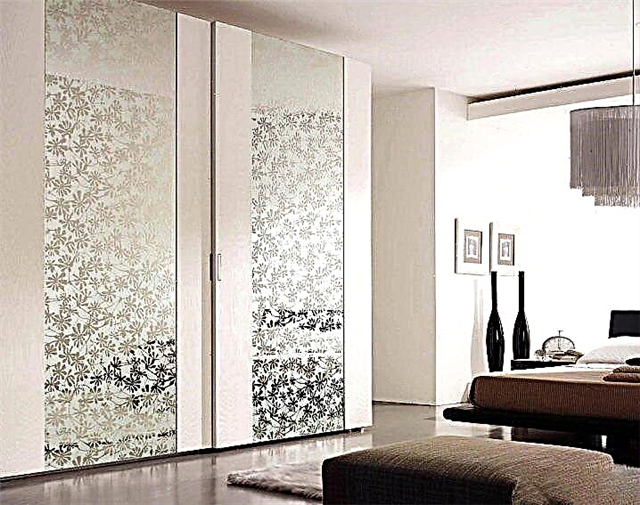

A square laminate is a flooring consisting of plates 60x60 cm in size. This form is very convenient for assembly and suitable for finishing all types of interior. The structure of the laminate includes 4 layers:

- The top melamine or acrylic layer is a colorless resin film that performs a protective function and determines the strength class of the laminate. This layer ensures the safety of the plate from environmental influences (mechanical damage, ultraviolet radiation and moisture).

- The decorative layer consists of a paper or polymer base on which the drawing is applied. It depends on it the appearance of the lamellas. Modern manufacturers offer all kinds of colors and patterns to simulate the texture of stone, metal, wood or textile.

- The supporting base consists of a fiberboard, the rigidity of which affects the durability of the finishing material. At the ends of this layer, special projections are made for durable adhesion of the square sections to the floor covering.

- The base layer is made from resin-impregnated moisture-resistant paper. With its help, the load on the plate is distributed so that it is possible to prevent the occurrence of deformation.

To meet the individual needs of consumers, the modern building materials market offers several varieties of square laminate with a more complex structure. They are equipped with heat-saving, soundproofing layers or an additional protective film.

Before buying a square-shaped laminate flooring, it is important to study the features of its operation. Only knowing all the positive and negative sides of the finishing material, it is easy to make the right choice.

Benefits

Almost immediately after the appearance of building materials on the modern market, square-shaped laminated panels were able to prove themselves from the best side, thanks to a number of positive qualities, among which the following are most relevant.

Easy to install

Large square flooring is suitable for almost any type of flat and dry surface. There is no need for its preliminary processing. The plates are equipped with locks on all sides, so each person will be able to carry out high-quality styling, knowing certain stages of work.

High strength and stabilizing performance

The composite components of a square laminate are of high density, so it does not collapse under the influence of chemical solvents, does not deteriorate after applying abrasive detergents. The coating is not erased, it is not subject to damage in case of accidental fall of sharp objects. The floor, for the finish of which the class of laminate was correctly selected, is able to withstand the pressure of heavy furniture without deformation. This is especially important if the coating is placed in a room intended for a large number of people.

Security

The laminate does not include flammable substances. It cannot become a source of ignition in the hot season. The floor will remain safe even when a spark hits its surface, a burning candle flips over or an unquenched cigarette is dropped.

Affordable cost

The affordable price combined with durability makes this material an excellent alternative solution compared to the cost of flooring made of natural wood, stone or ceramic. According to its characteristics, it is not inferior to floorings made of expensive natural materials, so the laminate is considered to be one of the market leaders in low-cost flooring.

High moisture resistance

A square laminate flooring is successfully used in the design of rooms with high humidity. Water-resistant varieties of laminated floor coverings do not lose their strength in the sauna, near pools or in the kitchen, where cleaning with water is constantly required.

Ease of cleaning

Square laminate floors can be looked after without special cleaning agents. Substances entering the coating do not penetrate its surface and have no effect on it. They are easily washed off with a moderate amount of water or with a slightly damp cloth.

A wide range of colors

A wide selection of color palettes makes it possible to embody all design ideas, work with any form and type of premises. In appearance, the floor made of this material has the maximum resemblance to a similar finish made of stone, leather, precious wood or fabric.

Disadvantages

In some cases, when using flooring from large squares of the laminate, its disadvantages appear:

- The non-waterproof type of laminate can deteriorate when exposed to a large amount of moisture, so it is not recommended for decorating bathrooms and other rooms where a lot of water regularly gets on the floor. Especially vulnerable areas at the joints of plates. They swell when water gets inside and require replacement of the floor covering.

- Laminate has unnatural components, and therefore it may not be suitable for people who prefer to see mainly natural finishing materials in their interior.

- The floors from the square laminate begin to creak if the builders do not follow the basic rules for its installation. A similar defect also occurs due to the fact that the lamellas are placed on uneven or wet surfaces.

Durability, aesthetic qualities and high fire safety performance of a square laminate make it possible to achieve any set goals during the repair. This relatively new finishing material rightfully occupies a leading position in the modern flooring market. These raw materials are considered worthy of purchase.

See how to lay a square laminate in the next video.