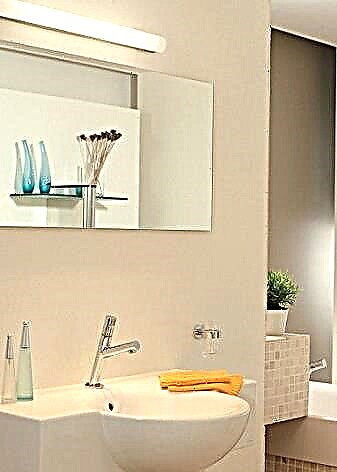

PVC panels are a popular material for redecorating rooms. This circumstance can be explained by their low cost, ease of installation and a variety of colors. Using this material, you can quickly and inexpensively repair a small office, utility room, decorate the walls in a store, and the like. However, such panels are very often used for quick and practical bath repairs. You can do it yourself, but it’s better to collect complete information on how and how to glue plastic to the wall before work.

PVC panels are a popular material for redecorating rooms. This circumstance can be explained by their low cost, ease of installation and a variety of colors. Using this material, you can quickly and inexpensively repair a small office, utility room, decorate the walls in a store, and the like. However, such panels are very often used for quick and practical bath repairs. You can do it yourself, but it’s better to collect complete information on how and how to glue plastic to the wall before work.

Description of PVC panels

The abbreviation PVC stands for "polyvinyl chloride." In fact, this is ordinary plastic, which was given the desired shape during production. PVC panels have been used as a finishing material for many years. This was made possible thanks to the undoubted advantages that the panels possess. Among them are:

Durability, service life up to 10 years.

Durability, service life up to 10 years.- Easy to care.

- Environmental friendliness.

- Moisture resistance.

- Fire safety.

- Resistance to low and high temperatures.

- Good soundproofing.

- Can be mounted on different surfaces and the like.

Many buyers also like the fact that a huge number of colors are presented in stores, and a variety of patterns are applied on the panels. If there is a desire to make an inexpensive, but beautiful repair, then this material will be a good choice. The main thing is to choose a good manufacturer and pay attention to the presence of possible defects in the goods. The panels are easy to buy and, importantly, easy to install.

There are two main ways that you can attach plastic panels to the wall:

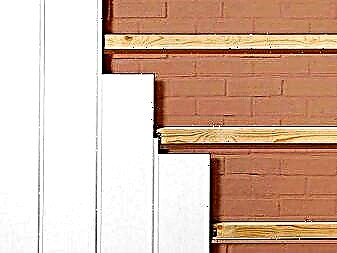

Attaching panels to the frame. This can be done mechanically, that is, using self-tapping screws, nails or staples. The crate itself can be metal, wooden or plastic. Also, the panels can be glued to the frame, which in this case will play the role of a wall equalizer. This method of fastening - to the crate - has its pros and cons. Those who don’t want to fiddle with the installation of the frame for too long and lose precious square centimeters in the bathroom can choose a different path.

Attaching panels to the frame. This can be done mechanically, that is, using self-tapping screws, nails or staples. The crate itself can be metal, wooden or plastic. Also, the panels can be glued to the frame, which in this case will play the role of a wall equalizer. This method of fastening - to the crate - has its pros and cons. Those who don’t want to fiddle with the installation of the frame for too long and lose precious square centimeters in the bathroom can choose a different path.- Gluing to the wall. This method has almost no effect on the area of the repaired premises. But he has his limitations. The walls should be even, dry, and the adhesive should be well selected, then repair work will give the correct result.

It must be understood that not every glue is suitable for attaching this finishing material. Some formulations can damage plastic or withstand moisture. Therefore, it is better to know in advance than gluing PVC panels to the wall.

What to look for when choosing glue

In order for plastic panels to last for a long time and have a presentable appearance, you should seriously take the choice of adhesive. It is worth noting that in construction stores you can find adhesives that are designed specifically for the installation of PVC plates. However, a situation may arise when such a product is not available or the landlord has some preferences of his own.

In order for plastic panels to last for a long time and have a presentable appearance, you should seriously take the choice of adhesive. It is worth noting that in construction stores you can find adhesives that are designed specifically for the installation of PVC plates. However, a situation may arise when such a product is not available or the landlord has some preferences of his own.

Usually a question what glue to useare puzzled by those who are going to do the repair themselves. The choice of means for fastening, of course, is important, but do not forget about other conditions.

The adhesive composition for PVC panels should have the following properties:

After drying, it should be transparent so as not to spoil the appearance of the finish.

After drying, it should be transparent so as not to spoil the appearance of the finish.- The composition used should be well resistant to moisture, temperature extremes, cold and the like.

- It is important that the glue sets quickly.

- Bonding quality should be as high as possible.

- It is also worth considering the durability of the mount.

- The glue used must be safe for health, so it is worth abandoning toxic compounds that have a strong odor.

It is worth having antibacterial additives in the glue. A correctly selected composition will guarantee that the decoration material is well attached to the wall and the panels will decorate the room for many years, despite the aggressive effects of water and temperature extremes.

Adhesive for PVC panels: which is better

In household stores presented wide range of adhesives. Some of them cannot be used for fastening plates, as they can cause them to deform and adversely affect their appearance.

But there are a number of compoundswhich are well suited for fastening plastic panels:

Kleiberite 636. It is not afraid of water; only one side must be treated during application. Made from synthetic resins. A big advantage is its safety for health.

Kleiberite 636. It is not afraid of water; only one side must be treated during application. Made from synthetic resins. A big advantage is its safety for health.- Emfikol 34012A. This adhesive with a viscous consistency is designed specifically for fixing PVC panels. It has good adhesion to such material. It is very durable, while colorless.

- Crystal moment. This is a fairly expensive composition, but it glues the plates very well to any surface. At the same time, it is colorless, so this glue can be safely used to attach finishing materials from polyvinyl chloride.

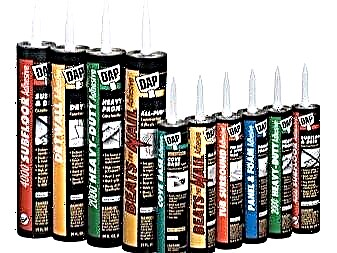

- Liquid Nails. This adhesive will be described below..

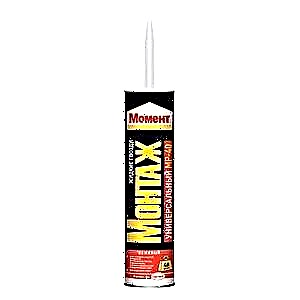

Other types of adhesives are also available on the market.. Some praise Moment Montage and Titan. When buying, it is important to understand that the high price of the composition will not be a guarantee that it will be suitable for decorating PVC wall panels. You should carefully read the labeling and instructions for glue, consult with the seller. If even after the purchase there is any doubt or the product was purchased earlier, donated, it remains from the last repair - it is better not to risk it. How the adhesive acts on polyvinyl chloride can be learned through experience. It is enough to apply the composition to a small surface of the plate and see the reaction of the plastic to the glue.

A few words about PVC panels

The manufacture of these products is carried out from household safe eco-friendly polyvinyl chloride, which can be used for decoration inside and outside buildings.

Polymer material has a lot of useful characteristics:

- The increased water resistance.

- Long service life: about 15-20 years.

- Resistance to high and negative temperatures (operating range: from -35 to + 75 ° C), ultraviolet light, mechanical loads of various types, direct influence of an open flame.

- Ecological purity (when using does not emit any harmful substances).

- Easy installation, transportation, care.

- Possibility of fixing with the use of glue for PVC panels on brick, concrete, block, wooden surfaces and walls / ceilings from other materials.

- Good soundproof qualities.

- A great option for flush-mounted wiring.

Important! It is forbidden to decorate the premises with PVC panels if evacuation must take place through them during emergencies (hallways, landings, corridor rooms, entrances, etc.). The requirement is relevant only for public places.

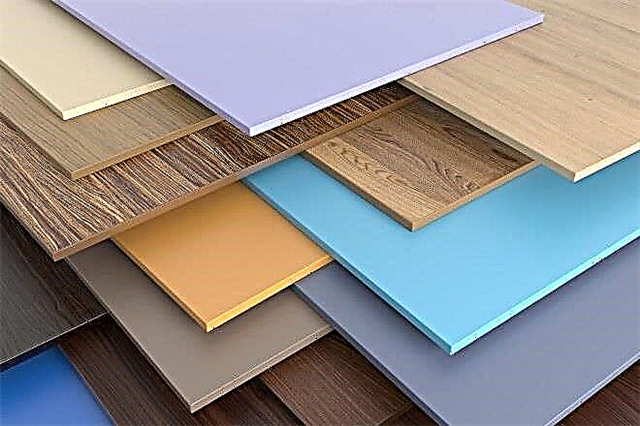

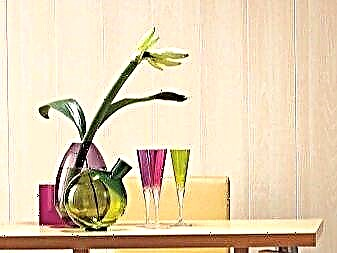

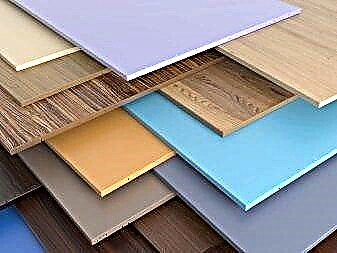

PVC boards on the market are very diverse. They can have different shapes, dimensions, colors, so you can easily choose the right option for use in different styles of interior.

Material characteristic

Polyvinyl chloride or PVC is a modern finishing material. The service life of such panels with proper installation reaches 10-15 years. They are resistant to temperature extremes, moisture, are not afraid of mold and fungus. They are durable, withstand mechanical stress. PVC provides good sound insulation, and this is not all the advantages of the finishing material. Basically, it serves to repair the bathroom and the bathroom, but it is also used in the decoration of loggias, balconies, offices and other premises.

The stores offer a wide range of plastic panels in different colors and shapes. They can be smooth or voluminous, with print or plain. The material is popular due to its affordable price.

The installation of such panels is carried out either on self-tapping screws, or on special fasteners - brackets and clamps. An alternative is glue for PVC. It is convenient to work with it, it allows you to carry out repairs with your own hands without extra time and money. Even one who does not have great knowledge in the construction business will cope.

What can I fix PVC panels on?

When choosing which glue for PVC panels is better, you need to consider other ways of fixing plastic products. This material is universal in application and installation, therefore, it can be fixed in different ways:

- Nails, screws. The most common method that provides clear and durable fasteners. If temperature differences are observed in the room, it is better not to use nails, because the products will undergo warpage and deteriorate over time.

2. Clammers. They can be used for wood grating. Temperature differences in such a situation do not have any negative impact.

3. Glue. Decorative panels connect to almost any surface if the wall or ceiling is aligned. If the base surface has defects and significant irregularities, then you need to build a crate and stick plastic products on it.

Many experts do not recommend using clamps, nails or self-tapping screws to fix plastic panels. This is due to the fact that the fasteners in this situation will be too noticeable, as a result, the finishing material will look ugly.

Attention! It is strongly not recommended to use self-tapping screws, nails and other types of metal fasteners, if finishing work in a room with high humidity indicators. In such a situation, characteristic spots with traces of rust will appear in places of attachment over time, which will be extremely difficult to get rid of.

Glue selection

Plastic is a lightweight material, so there is an erroneous opinion that it will be held on any composition. But for fixing PVC, especially in the bathroom, a product with increased strength and a number of special characteristics is required.

What should be the glue for PVC panels:

- Firstly, moisture resistant. Conventional glue will not withstand constant humidity. Only moisture-resistant glue will provide long-term and reliable fixation of the panels in the bathroom and similar rooms.

- The composition must withstand a wide range of temperatures and their frequent fluctuation.

- A high degree of adhesion is necessary for strong adhesion.

- It is good if among the components there are antibacterial additives. Due to the increased humidity, a favorable environment for the reproduction of bacteria is formed. Good glue will prevent the spread of mold and mildew.

- UV resistance also plays a role.

- The glue should be easy to apply. It is good when there is a special tip on the package.

- The transparency of the composition speaks in its favor.

- The quicker the grasp, the better. Ideally, after 10 minutes after attachment, the panel will clearly lock onto the wall.

- The composition should not be toxic substances, a good indicator is the absence of a pungent odor.

The quality of the selected adhesive directly affects the stability of the finishing material. The panels themselves can serve up to 10, and sometimes up to 15 years. If the glue is chosen incorrectly, then the shelf life of the finish will be significantly reduced.

Features of PVC panels

Plastic PVC panels - a beautiful, high-quality, cheap finishing material, consisting of reliable and resistant to mechanical damage polyvinyl chloride. The decorative pattern, applied to the front side by the method of monochrome thermal printing or decorative lamination, is coated with a paint that does not create glare and reflection, or glossy paints and varnishes. The protective layer of varnish increases the strength of the structure to mechanical damage and ultraviolet radiation.

The panels are divided into wall and ceiling. Wall panels are durable, thick and resistant to mechanical stress. Ceiling options include thin panels, which are fairly flexible materials.

Among the huge number of advantages, professional builders distinguish the most significant positions:

- universality and wide scope - the ability to use for finishing any surfaces for various purposes: walls, floors, door and window slopes, interior items,

- affordable price,

- moisture-proof and vapor-tight properties,

- Long service life

- resistance to liquid cleaners

- strength,

- high sound insulation and heat conductivity,

- a huge range - the production of materials of different textures, sizes and colors,

- the ability to hide surface defects, wiring and pipes,

- resistance to temperature fluctuations,

- environmental safety - the absence in the technological process of phenol-formaldehyde resins and the coating of sheets with water-based paint,

- simplicity and speed of installation - special glue is used on flat surfaces for fixing, to mask defects on the working surface of the panel they are mounted on a wooden or metal frame,

- aesthetic appeal.

Disadvantages:

- fragility of panels at low temperatures and mechanical damage,

- ignition on an open fire with the emission of toxic and toxic smoke,

- color change under the influence of ultraviolet rays,

- bad smell of new designs,

- unwanted use in children's rooms and bedrooms.

Manufacturers produce several types of panels with different connection methods:

- seamless - have a flat surface with inconspicuous joints,

- embossed - have slight discrepancies,

- rust - seamless panels with a chamfer.

PVC finishing material is plain, varnished, with a printed pattern and laminated.

The building materials market offers the buyer a huge range of panels.

For the correct selection of the required material, it is necessary to take into account some of its characteristics:

- product size

- lack of defects

- number of stiffeners,

- type of fastening

- mass

- composition,

- price range

- manufacturer.

PVC panels are a budget option for finishing different rooms with a simple installation method.

Product Examples

There are several proven manufacturers that produce special glue for plastic:

- Universal adhesive for plasticKleiberit on synthetic resins. Sold in tubes with a convenient nozzle. It has an affordable price, while it fixes PVC well, is not afraid of moisture and dries quickly. The composition is safe.

- Glue «Crystal moment". Also a universal glue, it can attach a plastic panel to almost any base. The advantage of the composition is that it is transparent.

- Another Moment glue is liquid nails (“Mounting"). Corresponds to its name. Strongly connects even poorly matching materials. There are samples for both indoor and outdoor use.

- «Emfikol"- a special composition for working with polyvinyl chloride. Colorless, viscous, forms a strong connection of plastic with the surface.

- Mitrefix - moisture resistant alternative composition. Forms a strong seam.

The main thing in choosing glue is the mark on the package that the composition is suitable for working with plastic.If you are not sure about the abilities of the glue, consult a specialist consultant, read the instructions. It is recommended to buy glue only in the construction departments, so as not to get a fake or low-quality goods.

How to install PVC panels on glue?

If problems with the choice of glue for plastic panels usually do not arise, then installation work can cause some difficulties. The work is carried out in several successive stages: preparation of the surface and the plastic panels themselves, installation, the final stage.

How to prepare the surface?

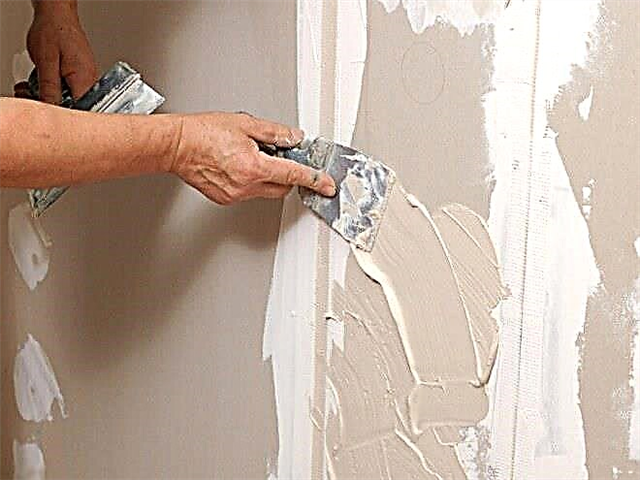

Before gluing PVC wall panels, it is necessary to prepare the surface. First, you need to evaluate it, find all the bumps and other defects. If they are insignificant, then the surface must be leveled or puttyed. In case of serious irregularities, it is recommended to call the crate.

How to prepare PVC panels?

Before starting gluing work, PVC wall panels must be left in the room where work will be carried out for about half a day or a day. Then, the products are cut into the necessary segments, degreasing the inner side to ensure better adhesion. PVC panels can be degreased with alcohol-based compounds so that the adhesive holds the product better during use.

Bonding process

If PVC panels are attached directly to a leveled surface made of concrete or other material, then glue must be applied to the back of the products pointwise, pressing them to the surface. When using the crate, the back side of the PVC panels should be treated with glue only in those places where they come into contact with it. If necessary, you can use additional mounts in the form of brackets or screws.

Final stage

Regardless of what kind of glue was used to fasten the panels, at the end you need to fix the finish profile and remove the adhesive residue from the products. On this, the process of gluing PVC panels can be considered completed.

If after the installation work ugly joints and gaps remain, they can be repaired using the appropriate decorative plastic profiles. Such profiles are sold everywhere - you can choose an option that in color and performance will fit the style of decoration.

On video: Installation of pvc panels directly on the wall.

How to mount PVC panels

It all starts with the preparation of the walls, this is the foundation of a successful wall cladding. If the surface does not meet the proper requirements, then the plastic panels will not last long on them. Where to begin:

- Walls need to be cleaned of old finishing materials, leveled and puttyed. The smoother the surface, the more beautiful and reliable the result will be.

- The next step is to cover the wall with a deep penetration primer.

- Now leave the walls to dry. Although glue and PVC are not afraid of moisture, gluing is recommended only on a dry surface.

Important! On the walls before gluing PVC panels there should be no dust and grease.

Panels also need a little preparation. All parts must be clean and degreased. Immediately after the purchase, installation is not worth it. The material must lie for at least 12 hours at room temperature. This is called acclimatization.

Universal adhesive for plastic Kleiberit

howglue PVC wall panels:

- The material is cut in height and length of the room. Make markings on the front side to get even details.

- The wall is marked so that the first part stands perfectly evenly - the level of all subsequent panels will depend on it.

- If the lining with a pattern that is made up of different fragments will not be an extra water marker (which is easily erased), number the details.

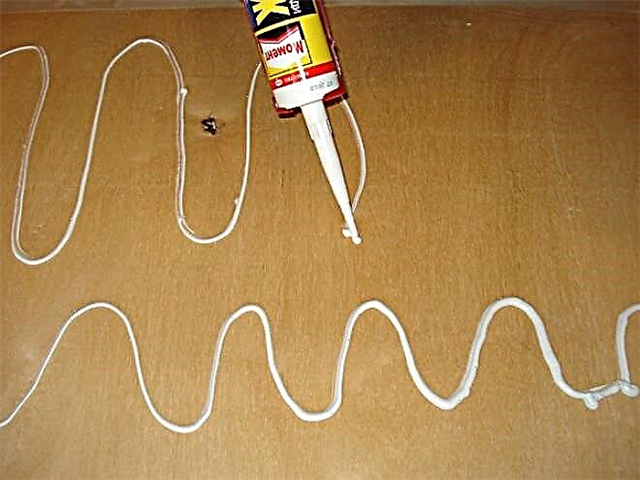

- On each panel, glue is applied in a dotted or dashed line over the entire surface.

- The material is firmly pressed against the wall and holds the necessary amount of time. In the instructions for glue this should be indicated. Clay "Moment" works faster than others. The maximum time that you need to hold the panel is 10 minutes.

- Installation starts from a corner or door.

- If excess glue is found after work, it is removed with a damp piece of cloth or a sponge - it is best to do this immediately, and not after the entire lining has finished.

- After complete polymerization of the adhesive, the protective film is removed from the coating.

Liquid Nails Installation

Advice! In some cases, it will be appropriate to apply glue to the wall itself. Before this, it must be well degreased. The surface is covered with a thin layer, then it is slightly dried. Such a measure will enhance adhesion between materials.

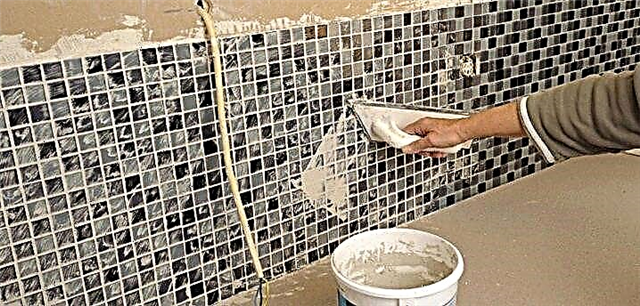

PVC mosaic

Mosaic masonry always looks spectacular, but natural materials are quite expensive. Mosaic can also be made of PVC panels, and this is done easier than it seems at first glance. Installation is carried out both in the kitchen and in the bathroom. This is a worthy replacement for ceramics, PVC is also not afraid of moisture, is resistant to temperature extremes and looks decent. Another important plus: the mosaic decorates small irregularities and wall defects due to plasticity.

How to stick a plastic mosaic to the wall:

- Panels can be installed directly on the wall.

- The surface must be clean.

- Sheets are cut with a construction knife.

- Each sheet is covered with glue.

- The part is pressed firmly against the wall until it is fully engaged.

- The time of complete drying is 2-3 days.

- When installing mosaic parts, joints will appear. They are treated with sealant.

Installation of PVC panels is a good solution for quick repair of premises with your own hands. It is not enough to select high-quality material, related tools can more likely affect the result. So, the stronger the glue, the longer the plastic panels will last.

The most common mistakes when installing PVC panels

If the work on gluing plastic PVC panels is done independently, then many people in this case make the same mistakes, the consequences of which are very difficult to deal with in the future. In rare cases, you have to redo everything at all.

The most common errors include:

- Wrong choice of adhesive composition (how to glue PVC panels can be clarified when buying them in a store from a seller’s consultant). If the glue was not selected correctly (for example, if a universal glue mixture is used), then it is highly likely that plastic products will begin to fall off from the walls or ceiling in a few weeks or months. In this case, everything will need to be re-glued again.

- Bonding PVC panels in the bathroom to glue that is not waterproof. If the installation of plastic products is carried out in a room with high humidity, then the adhesive for installation must be selected accordingly - with waterproof characteristics. When using a non-waterproof adhesive, the products will fall off after a few days.

- Excessively strong bending of PVC panels during installation. When carrying out installation work, make sure that plastic products do not bend too much. If they are strongly bent, then outwardly it will not look very beautiful. In addition, there is a high probability of their failure after some time of operation.

- Using the wrong tools to trim PVC panels. Cutting plastic products is strongly recommended only with a hacksaw, the tooth pitch of which is not more than 1 mm. If for cutting you choose a standard hacksaw for metal or wood, then PVC panels will form nicks and burrs in the places of cut.

- Use for cleaning PVC panels organic solvents. Do not use organic solvents to clean plastic products from dirt, glue or paint stains. In this case, characteristic spots will immediately appear on the material.

Installation of PVC panels on a wall or ceiling is a simple and relatively easy process. The main thing here is to choose the right good glue from the best Russian or foreign manufacturers.

Liquid Nails

Probably, not a single repair can do without this fixing composition. This tool has proven itself well in finishing work using plastic panels. Using liquid nails is very simple, while they perfectly attach the polyvinyl chloride to the wall or crate. But at the time of purchase, you must carefully select the correct composition. Some products are too strong, and their use can lead to swelling of the plastic surface.

Probably, not a single repair can do without this fixing composition. This tool has proven itself well in finishing work using plastic panels. Using liquid nails is very simple, while they perfectly attach the polyvinyl chloride to the wall or crate. But at the time of purchase, you must carefully select the correct composition. Some products are too strong, and their use can lead to swelling of the plastic surface.

Among the liquid nails, which are usually used for gluing PVC finishing materials, we can name the following:

Liquid nails 601. They can be used when working with different types of materials, including PVC. The agent dries up within 10 minutes, which gives time to correct errors if the plate was attached unevenly. However, some masters do not recommend using this composition when repairing a bathroom and toilet, since it has insufficient moisture resistance.

Liquid nails 601. They can be used when working with different types of materials, including PVC. The agent dries up within 10 minutes, which gives time to correct errors if the plate was attached unevenly. However, some masters do not recommend using this composition when repairing a bathroom and toilet, since it has insufficient moisture resistance.- Liquid nails 901. This tool can be used both for interior decoration and outdoor work. Its main advantages are versatility, durability and strength. Such a composition is able to hold even heavy coatings.

- Liquid nails 915. This substance is ideal for repairs in the bathroom or other rooms where there is high humidity. The composition does not allow water to penetrate the wall surface, which protects the room from mold and other troubles.

In general, the use of such funds is justified. Perhaps, during the installation of PVC plates there will be some subtleties. It is better to read the instructions in advance so that the polyvinyl chloride is firmly attached to the surface of the wall.

How to glue plastic panels on the wall

The process of gluing PVC plates is quite simple and can be done independently. Here, the preparatory work and the quality of the glue play a big role. This will be the key to the fact that the finish will be firmly attached.

The process of gluing PVC plates is quite simple and can be done independently. Here, the preparatory work and the quality of the glue play a big role. This will be the key to the fact that the finish will be firmly attached.

First you need to thoroughly clean the walls of dirt, paint and the like. The surface should be as smooth as possible, since small pits and scratches can significantly reduce the bonding strength. If there are defects on the wall, then they must be thoroughly putty. At the end of the work, it is necessary to cover the surface with a primer and allow the wall to dry.

Before starting work, PVC panels must be cut from the front side to get everything neat. Mounting is done from a corner or door. The glue itself is applied with dots or a dashed line. If liquid nails are used, it is better to apply a grid to the inner surface of the plate. After that, the plate is firmly pressed against the wall; during operation, the panel should not bend too much.

If there are any joints after gluing, then it is better to process them with silicone sealant. Only after finishing work can the protective film be removed from the material. To make the room look good, you can install ceiling and floor skirtings.

Neatly and tightly glued PVC panels will decorate the bathroom for many years and protect the walls from excess moisture.

Usability

When buying tools for gluing panels, you should pay attention to what the packaging of the material is.

It will be convenient to use the composition if it is viscous and passes well through the narrow neck of a bottle or tube.

Universal adhesive for plastic Kleiberit

A distinctive feature of the universal product is its good resistance to high humidity. Hence, they recommend an adhesive product for installing plastic panels in the bathroom. The glue is based on artificial resins without harmful additives. The composition is uniform in mass uniformity and quick setting.

Crystal Moment

The advantage of a quality product in it:

- water resistance

- transparency

- temperature tolerance of both -40 and +70 degrees,

- resistance to aggressive influences.

The only negative glue in its flammability. Therefore, when working, it is necessary to use the product away from heating appliances. When working with glue, keep the windows open.

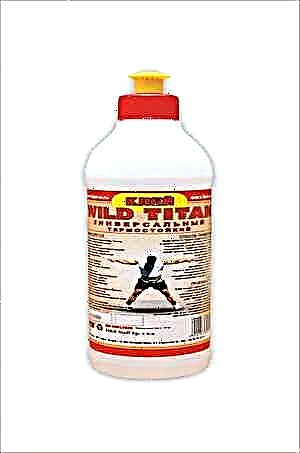

Titan wild

The demand for glue is associated with it:

- efficiency in construction and repair work,

- resistance to harmful influences,

- elasticity after drying,

- high environmental friendliness

- economical use.

When working with glue, a reliable hitch with plaster and concrete is provided.

How to install correctly

Preparation for installing panels on the walls is by assessing the quality of their surface. It is impossible to stick on the walls if dust and dirt are on them. Therefore, before gluing, a period of surface preparation is needed. It is necessary to clean the walls of old cladding, dust. If there are slight irregularities, defects, then they should be leveled with putty.

The next step is to conduct a deep primer. Before gluing the panels, the walls must be dried. Gluing on wet surfaces is not recommended. If you do not want to smooth the surfaces for gluing the panels, you should carry out the crate of the walls. It is difficult to make and install it independently, therefore, the installation should be entrusted to a specialist. It should be borne in mind that the room will decrease in size.

Panels need acclimatization after purchase. At least 12 hours, they are laid down in the room before gluing.

Features of gluing wall panels

Turning to the process of installing panels, it is necessary to mark the 1st strip. Installation starts from a corner or door. When the part rises perfectly perfectly, the following sheet panels will fall in accordance with the set level. Instead of a sheet of plastic, a skirting board is used in the corner. They are glued at an angle of 90 degrees.

Glue dotted or dotted pass over the entire surface of each panel. After application, press the material against the wall and hold until the adhesive sets completely. Immediately try to remove the excess adhesive that protrudes from under the sheets of plastic. Later, after drying, it’s more difficult to remove droplets.

Glue is applied to the wall if they want to improve the adhesion of materials. In this case, the surface of the walls degrease. If plastic is installed on the crate, then it is also degreased and lubricated with adhesive after drying.

How to glue a PVC mosaic

For bathroom and kitchen, facing ceramic tiles is expensive. Then you should pay attention to the PVC panels. You can choose a picture according to your taste. And the mosaic on polyvinyl chloride will remain bright for a long time. And the material is highly resistant to moisture, temperature extremes, which allows not to make repairs for 10-12 years.

It will be necessary to glue strips with patterns, choosing so as to save the picture. It’s better to start from the corner. Glue the first panel or baseboard, and then align the remaining parts of the material. The wall turns decorative, it will become a true decoration of the kitchen, bathroom.

How to calculate material consumption

It is necessary to calculate the amount of glue for repair in advance. The surface area to be closed with PVC sheets is measured. On 2 linear meters of material, glue is applied with a thickness of 6 millimeters. If there are 300 milliliters of funds in the tube, then one copy is enough for 5 panels. To determine the number of sheets for pasting the walls, you need the help of a specialist. You can refer to the program "Calculator", thanks to which the number of sheets of plastic material is accurately calculated.

Is it possible to glue on sealant

Silicone sealants are used by many for gluing wall panels.Here it is worth paying attention to the composition of the product and whether it can be used as glue. Tubes with sealant are sold, which indicate what material can be glued with this product. But still, it is better to stop the choice on a special glue.

Silicone sealant is needed when you have to close the gaps and gaps between the panels. Use the material at the end after repair, when the gluing is over. The sealant will make the walls protected from moisture, harmful microorganisms.

Additional tips and tricks

The work of installing plastic panels requires certain skills and knowledge. It is worth listening to the opinion of experts who advise:

- when cutting the panels, turn them face up,

- hammer the nails during installation carefully so as not to damage the material,

- align the corners of the room before starting work,

- to degrease surfaces use an alcohol solution,

- glue or sealant to choose based on silicone, without a pungent odor.

Plastic panels will last a long time if properly mounted and glued. To wash them, foam from detergents is used. Abrasive preparations should not be used. Aggressive substances will spoil the surface of the plastic, erase the picture.

Composition selection criteria

The choice of glue for fixing PVC panels must be approached with all responsibility. The quality of the finish will depend on the composition used.

When acquiring a particular type of glue, it is necessary to take into account some requirements for such a composition.

- Like polyvinyl chloride, the adhesive mixture must have good moisture resistance. This property of the composition is important not only when the panels are installed in the bathroom. Such finishing material becomes dirty over time and must be wiped with a damp cloth or cleaning products, so the glue should not be afraid of contact with water.

- Despite the fact that the panels are lightweight, it is necessary to use high-strength compositions for reliable fastening.

- Resistance to temperature differences.

- It is desirable that the adhesive composition includes antiseptics.

- For polyvinyl chloride sheet panels, it is best to choose a colorless adhesive mixture. Such glue is suitable for fixing not only white panels, but also decorative models, as well as PVC mosaics.

- The glue should be environmentally friendly, without a sharp unpleasant odor. Alcohol-based mixtures are best avoided.

When choosing a suitable glue, the purpose of the room where the panels will be installed is of great importance.

It is necessary to take into account the features of the operation of materials: temperature, humidity, exposure to direct sunlight.

"The moment of installation"

Under the brand "Moment" a whole line of adhesive compounds "Moment Installation" is produced. Mixtures differ in purpose, technical characteristics and color. All compositions are united by one common property - high reliability of fixing materials.

For PVC panels in this case, it is better to use universal modifications that do not have color. When choosing a suitable modification, you should pay attention to the fastening of which materials the composition is suitable. It is necessary to take into account not only the material from which the panels are made, but also the type of base.

The subtleties of installation work

PVC panels are fixed to the base with adhesive or on a pre-arranged crate. The first option is the simplest, since it does not require much time and serious effort. In addition, to make the crate, certain skills and craftsmanship are needed.

However, the method of fixing with glue has certain nuances. First of all, it must be borne in mind that the base must be level. Small defects are allowed, but differences should not be more than 0.5 cm. Care must also be taken to prepare the surface.

To do this, before starting installation work, the base is cleaned from the old coating, dirt is removed from the surface and degreased. Another important task in this case will be the choice of high-quality adhesive composition. If you use the wrong adhesive, the panels will not fix properly, and after a while the procedure will have to be repeated. For additional fixation when installing the panels, you can use mounting foam.

Whatever adhesive composition was acquired for fixing plastic panels, the principle of operation will be approximately the same. The difference can only be in the time of setting and drying of the glue.

Preparatory stage

Before starting installation work, it is necessary to prepare the base. If there are significant irregularities on the surface, then it is necessary to eliminate them with plaster and putty.

As an alternative, in this case, you can make the crate and stick the panels on it. It is also important to ensure that the base on which the finishing material will be attached is clean and fat free.

For better adhesion, the surface is recommended to be treated with a primer mixture. Before attaching the panels, the base must dry well. However, preparation in this case is needed not only for the walls.

The panels and adhesive composition, after they were purchased in the store, should not be used immediately - the materials should lie down at home at room temperature for some time.

Mount

The process of gluing PVC panels to surfaces such as concrete or wood is not particularly difficult. The most important thing is to correctly mark the base, accurately calculate the required number of panels and, if necessary, evenly cut the material into pieces of the desired size.

When it is necessary to attach the panels to the wall itself without the crate, the adhesive mixture is distributed over the entire back side of the finishing material, but not in a continuous layer, but in a dotted manner. If it is required to adhere the material to the crate, then glue is also applied to the back of the panels, but only in places of contact with the base.

During finishing work, it is necessary to monitor the front side of the PVC panels. If there will be glue on the material, then it must immediately be removed from the surface with a dry cloth.

How to glue PVC panels in the bathroom is described in the next video.

Types of glue

Mounting panels on special glue is a simple and inexpensive way for beginner builders to complete finishing work.

Adhesives for this type of finishing work must have some properties:

- moisture resistance - for reliable fixation of the structure in rooms with high humidity,

- resistance to temperature fluctuations and ultraviolet radiation,

- elasticity

- antiseptic properties and resistance to mold and fungi,

- economical and convenient packaging,

- high percentage of setting, transparency and adhesion,

- lack of an unpleasant smell and harmful substances.

Manufacturers of adhesives indicate on the packaging what types of work and materials they are suitable for. Illiterate choice of glue or poor quality of the composition will significantly reduce the period of operation of the structure, will lead to a change in color, structure and shedding of fixing means. The building materials market offers two types of glue: one-component and two-component. The first type is a ready-made solution, which is easy to apply and use. The second is a set consisting of an adhesive base and a thickener, a durable and reliable composition for professional builders.

Depending on the properties, adhesives are:

- fixing - fix the elements to the working surface,

- reactive - are used to work with large elements,

- contact - durable and reliable solutions,

- dispersion - adhesive is applied only on the surface of the base, which significantly reduces the consumption of the composition and reduces the finishing time.

The most popular products on the shelves of construction stores are liquid nails, products of the Titan brand, Moment Montazh glue, T type cold welding (type “Secunda” (for multi-component and multi-layer surface types), assembly foam.

The most popular adhesives with high positive reviews are liquid nails.

It has the following universal properties:

- environmental Safety:

- waterproof composition - it is used for finishing bathrooms of pools and kitchen aprons,

- consistency in the form of a paste with a transparent beige shade,

- antibacterial composition - prevents the development of mold and fungi in a warm and humid environment,

- low consumption: 50 g per 1 m2.

Rules for applying adhesive:

- Before starting work, it is necessary to degrease the surface with alcohol-based solutions,

- an adhesive composition based on a vinyl chloride polymer is used for plastic, and thermoplastic compounds are used for fixing rubber

- the composition must be applied evenly,

- the use of high temperatures will increase the percentage of setting of the structure and the working base,

- it is necessary to exclude the load on the surface for the first 24 hours.

Mistakes when choosing glue:

- incorrect calculation of the effects of loads on the structure,

- mismatch of glue type and type of coating,

- non-compliance with temperature ranges.

How to choose?

When choosing glue, the buyer must take into account the type of surface, operating conditions, price range of goods and some requirements for the adhesive composition.

Glue should have the following qualities:

- keep colorless after drying,

- possess high locking performance, securely fasten the structure,

- have resistance to temperature, sunlight and humidity,

- environmental safety is an important indicator when choosing glue.

For wall panels a glue gun with hot glue, liquid nails or non-expandable polyurethane sealants are suitable.

To carry out finishing work in the bathroom, experts recommend using only special compounds. Bathroom - a room with a complex microclimate with high humidity and temperature changes. The glue for PVC panels should have such characteristics as moisture resistance, resistance to temperature extremes and ultraviolet radiation, and also have increased antibacterial rates.

Particular attention should be paid to mounting mirrors in the bathroom. It is better to fix the mirror to concrete or tile with special adhesives based on resins and rubber, which do not damage the mirror surface, are resistant to moisture, have a short period and high setting strength, do not emit toxic substances.

For gluing floor coverings and sheet decorative materials manufacturers offer customers several types of adhesives:

- polymer - elastic, durable, resistant to the negative effects of the environment,

- polymer cement - strong and reliable composition,

- acrylic - strengthens the surface and lets steam through,

- polyurethane - consists of rubber, a universal composition for PVC panels,

- epoxy - mounting composition for external and technical use.

Application Tips

The preparatory phase is the key to high-quality and quick installation.

Before attaching PVC panels, it is necessary to complete the finishing work:

- clean the work surface from dust and grease, smooth and putty all defects,

- coat the base with a deep penetration primer,

- let the surface dry.

For fast and high-quality work, professional builders are advised to follow the following rules:

- mark the sheets on the front side to obtain smooth and accurate parts,

- identify and mark the place of fastening of the first sheet, start work from the door or corner of the room,

- number the details of the intended pattern,

- glue to be applied pointwise on the entire surface of the panel and wall,

- firmly pressing the material to the working surface, hold until the composition sets completely,

- remove excess glue from the surface,

- remove the protective film from the finishing material.

For the high-quality performance of finishing work, it is necessary to strictly adhere to the technological process and follow all the norms and rules for the performance of work - only then will the completed work bring moral satisfaction, and the material will last a long and reliable time.

About how to glue plastic panels when decorating walls in the bathroom, see the next video.

Durability, service life up to 10 years.

Durability, service life up to 10 years. Attaching panels to the frame. This can be done mechanically, that is, using self-tapping screws, nails or staples. The crate itself can be metal, wooden or plastic. Also, the panels can be glued to the frame, which in this case will play the role of a wall equalizer. This method of fastening - to the crate - has its pros and cons. Those who don’t want to fiddle with the installation of the frame for too long and lose precious square centimeters in the bathroom can choose a different path.

Attaching panels to the frame. This can be done mechanically, that is, using self-tapping screws, nails or staples. The crate itself can be metal, wooden or plastic. Also, the panels can be glued to the frame, which in this case will play the role of a wall equalizer. This method of fastening - to the crate - has its pros and cons. Those who don’t want to fiddle with the installation of the frame for too long and lose precious square centimeters in the bathroom can choose a different path. After drying, it should be transparent so as not to spoil the appearance of the finish.

After drying, it should be transparent so as not to spoil the appearance of the finish. Kleiberite 636. It is not afraid of water; only one side must be treated during application. Made from synthetic resins. A big advantage is its safety for health.

Kleiberite 636. It is not afraid of water; only one side must be treated during application. Made from synthetic resins. A big advantage is its safety for health. Liquid nails 601. They can be used when working with different types of materials, including PVC. The agent dries up within 10 minutes, which gives time to correct errors if the plate was attached unevenly. However, some masters do not recommend using this composition when repairing a bathroom and toilet, since it has insufficient moisture resistance.

Liquid nails 601. They can be used when working with different types of materials, including PVC. The agent dries up within 10 minutes, which gives time to correct errors if the plate was attached unevenly. However, some masters do not recommend using this composition when repairing a bathroom and toilet, since it has insufficient moisture resistance.